IV. Main Types of Equipment

1. Batch (Kiln) Dryers

Features: A full load of panels is placed inside, and the entire drying cycle is completed before unloading. Suitable for multiple wood species, specifications, small batches, or custom production.

Common Type: Track-based trolley kilns.

Advantages: High flexibility, relatively lower initial investment.

Disadvantages: Lower production efficiency compared to continuous dryers, potential batch-to-batch quality variation.

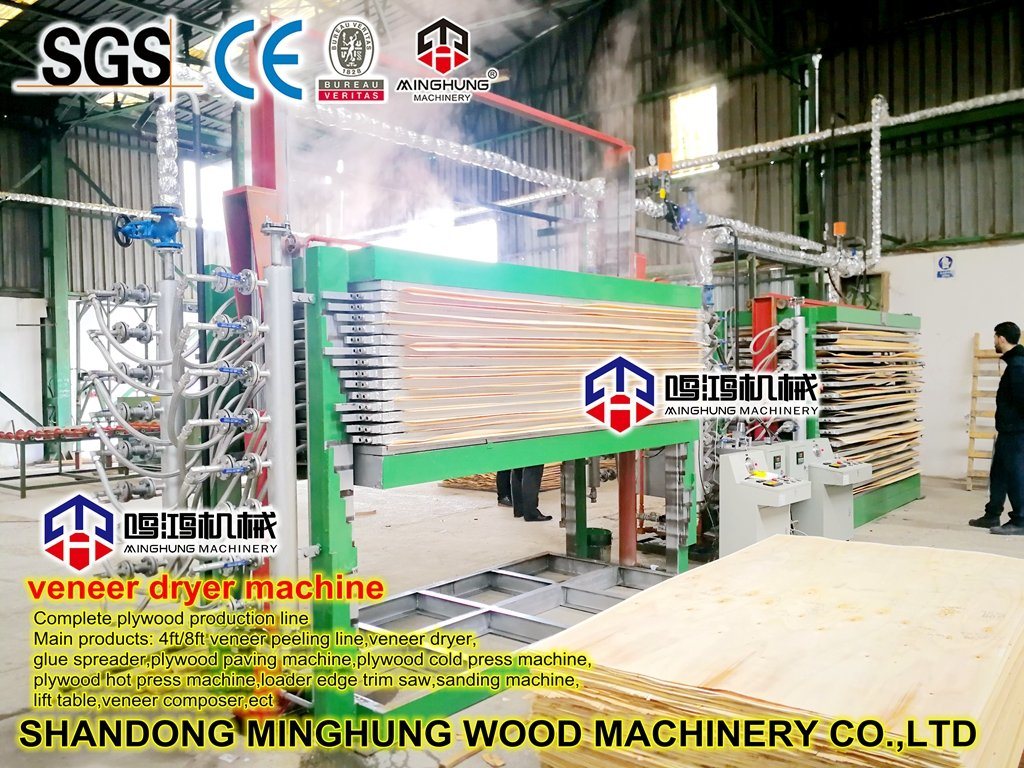

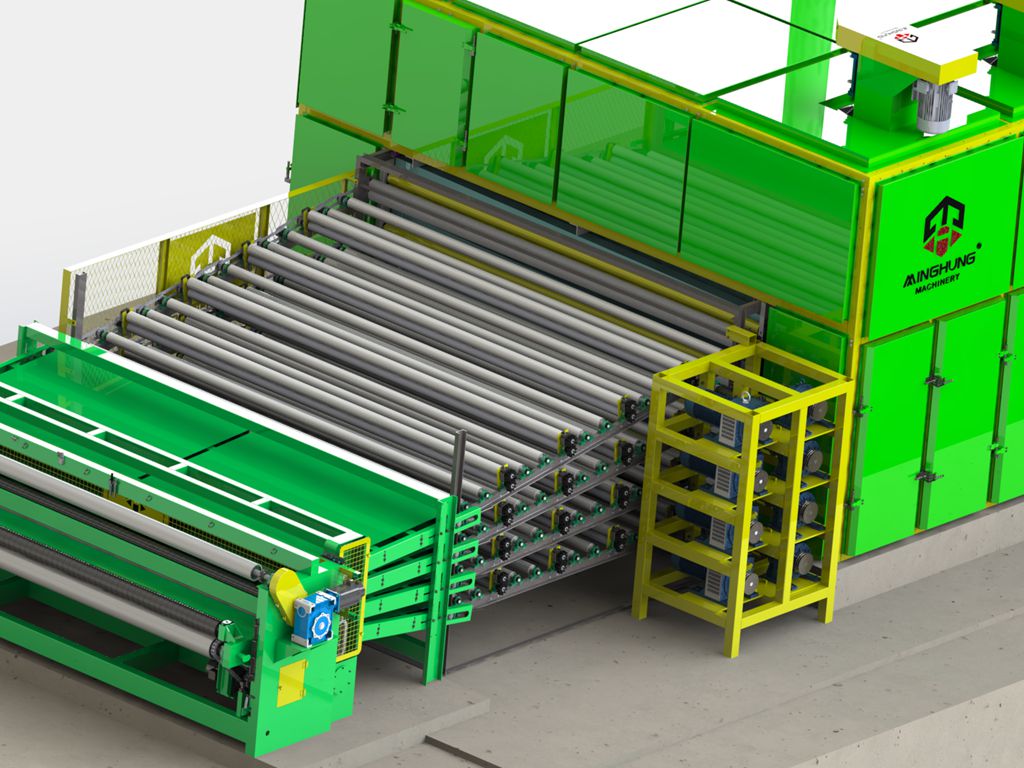

2. Continuous Dryers

Features: Panels move continuously through the dryer (typically on multi-tier mesh belts or roller conveyors) from inlet to outlet. Ideal for high-volume, standardized, single-species production.

Common Type: Multi-layer mesh belt continuous dryers.

Advantages: Very high production efficiency, high automation, uniform and stable drying quality, labor-saving.

Disadvantages: High initial investment, less adaptable to frequent product specification changes.