Main Components of the Production Line

A complete 8-foot x 4-foot (approximately 2440mm x 1220mm) plywood large panel production line is a highly automated industrial manufacturing system designed to efficiently process raw logs into standard-sized plywood sheets. Its core process involves peeling logs into veneers, which then undergo a series of steps including drying, gluing, layup, cold pressing, and hot pressing to ultimately form sturdy panels.

Log Processing Section:

Debarker: Removes bark from the logs to ensure a smooth, clean surface for peeling.

Cross-Cut Saw: Cuts long logs into sections of the required length for the peeling lathe.

Veneer Preparation Section:

Peeling Lathe: The core equipment of the production line. It rotates the log section at high speed while a sharp blade continuously peels it into a ribbon of veneer of specified thickness.

Veneer Clipper: Cuts the continuous veneer ribbon into sheets of the required width (e.g., 4 feet).

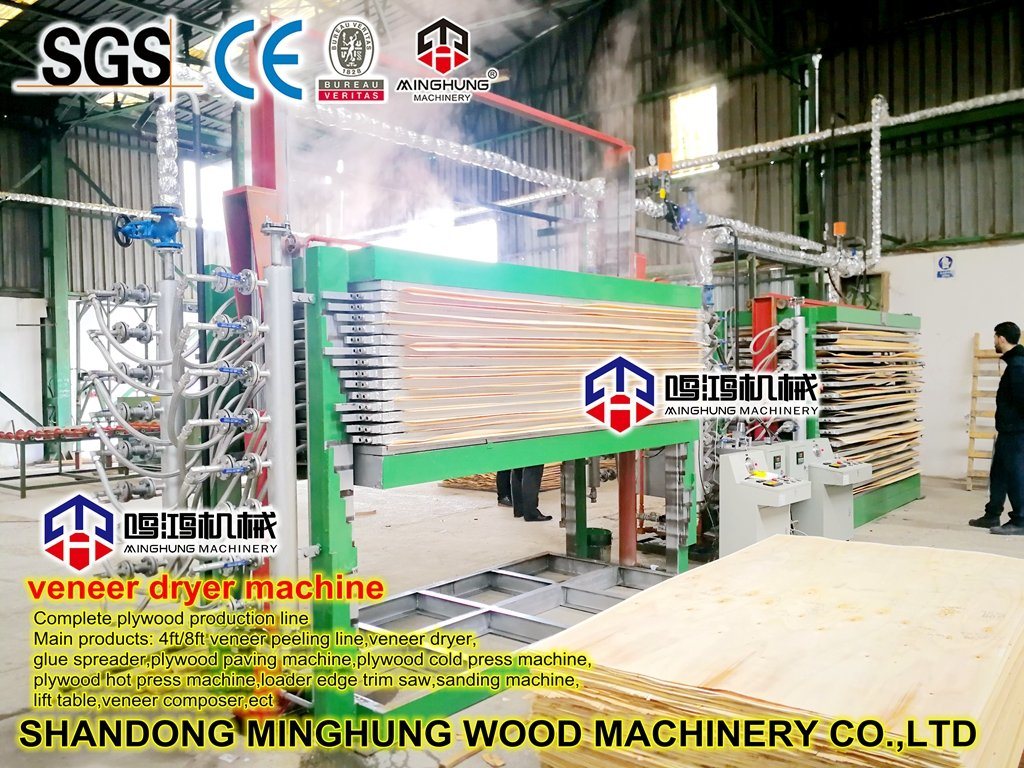

Veneer Drying and Treatment Section:

Veneer Dryer: Typically uses roller or mesh belt dryers to reduce the moisture content of the veneer from over 60% (in its green state) to 8%-12% using hot air, making it suitable for gluing.

Veneer Splicer/Patcher: Repairs defects in the dried veneer sheets and splices narrow veneer strips into full 4x8 foot sheets.

Gluing and Layup Section:

Glue Spreader: Applies adhesive (e.g., urea-formaldehyde, phenol-formaldehyde resin) evenly onto the veneer surfaces. A four-roller glue spreader is common.

Layup Line: Manual or automatic assembly equipment stacks the glued and unglued veneers according to the principle that the grain direction of adjacent layers is perpendicular, forming a mat (unc pressed panel).

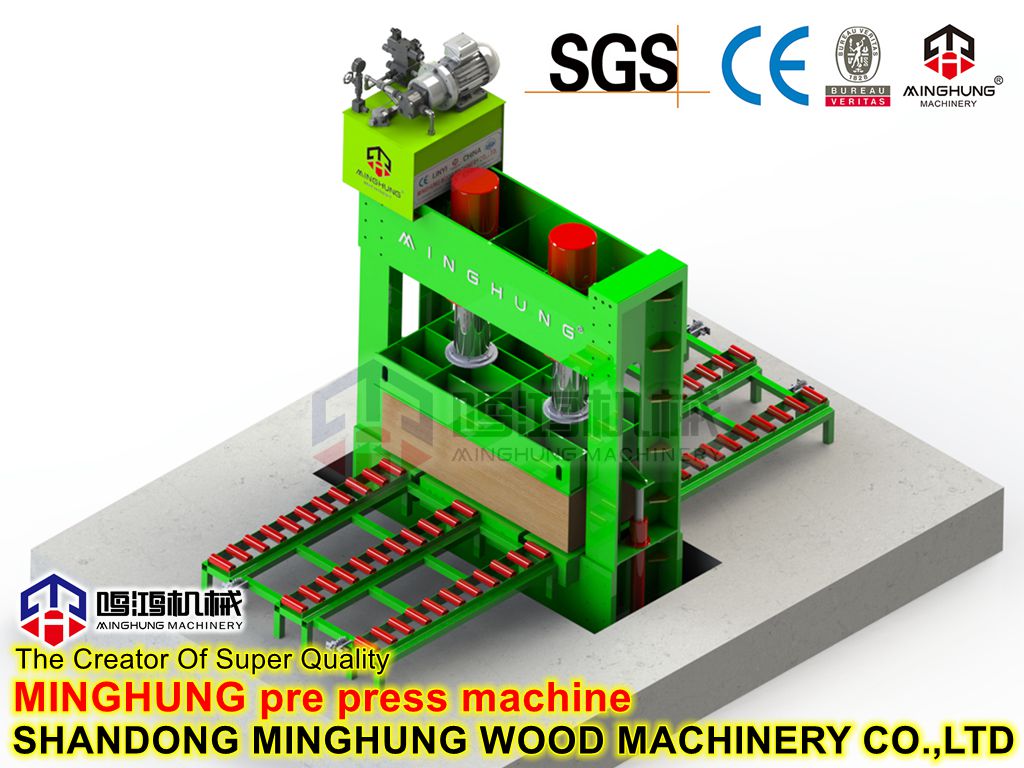

Pressing and Forming Section:

Pre-Press: Subjects the assembled mat to cold pressing, providing initial bonding and sufficient strength for easier handling and loading into the hot press.

Hot Press: Another core piece of equipment in the line. It applies high temperature and high pressure to the mat, causing the adhesive to cure quickly and firmly bonding the multiple veneer layers into a solid panel.

Finishing Section:

Cooling and Turning Station: Cools and turns the hot-pressed plywood panels to prevent warping.

Sanding Machine: Calibrates and finishes the panel surface through sanding, ensuring uniform thickness and a smooth surface.

Cross-Cut & Edge Trimming Saws: Trims the rough-edged panels to the precise final dimensions of 8x4 feet.

Control System:

The entire production line is controlled by PLCs (Programmable Logic Controllers) and computers, offering a high degree of automation to ensure production efficiency and consistent product quality.

1. Log Preparation: Logs are debarked and cross-cut into peeling blocks.

2. Peeling: Blocks are processed on the lathe into continuous veneer ribbons.

3. Clipping and Drying: Veneer is clipped into sheets and then dried to remove moisture.

4. Veneer Treatment: Dried veneer sheets are patched and spliced.

5. Gluing and Layup: Veneers pass through the glue spreader and are then assembled into mats according to the structural requirements.

6. Pre-Pressing: The mat is lightly compacted under cold pressure.

7. Hot Pressing: The mat is subjected to high temperature and pressure in the hot press, curing the adhesive and forming the final panel.

8. Finishing: Panels are cooled, sanded, and trimmed to size.

9. Inspection and Packaging: Finished products undergo quality inspection before being packaged and stored.

Production Line Characteristics and Advantages

High Efficiency: Automated continuous production offers much higher output compared to traditional manual or semi-mechanized methods.

High Quality: Precise control of process parameters results in products with uniform thickness, stable structure, and high strength.

High Material Utilization: Veneer patching and splicing reduce waste.

Standardized Production: Designed specifically for the most universal 8x4 foot size, meeting mainstream market demand.

Customizability: Capable of producing plywood of different specifications and end-uses (e.g., interior, exterior, marine grade) by adjusting peel thickness, adhesive type, and hot press parameters.

Construction Industry: For concrete pouring projects in real estate, bridges, tunnels, etc.

Furniture Manufacturing: As standard-sized substrate for cabinets, wardrobes, and office furniture.

Interior Decoration & Packaging: For making partitions, ceilings, and packing cases.