|

Product equipment

A complete production line specialized in manufacturing 3mm thick lightweight MDF boards consists of a series of precision equipment. Its core objective is to achieve high-precision, stable production of ultra-thin boards with low density while ensuring adequate board strength.

1. Raw Material Preparation and Fiber Preparation Section

Drum Chipper: This is the starting point of the production line. It is responsible for cutting raw logs, small-diameter wood, or wood processing residues (like slabs) into uniform process chips that meet the requirements for subsequent processing. Uniform chip size is the foundation for producing high-quality fibers.

Defibrator System (Thermo-Mechanical Pulping): This is the heart of MDF production. The wood chips are first steamed and softened in a preheating digester under high-pressure saturated steam. They are then fed into the main defibrator, where they are broken down into fine wooden fibers through the immense frictional force between large rotating grinding discs. For lightweight MDF, precise control over fiber fineness and length is crucial to achieve optimal fiber mat entanglement, which maintains strength at low density.

Fiber Drying System: Fibers exiting the defibrator have very high moisture content and must be dried. A rotary cascade dryer with a pneumatic conveyor is typically used. The wet fibers are suspended and rapidly dried in a stream of hot air, reducing their moisture content to a precise target range (usually 8%-12%). Drying uniformity is critical for final board quality.

2. Resin Blending and Mat Forming Section

Ring Blender: This is key equipment for achieving lightweight and eco-friendly properties. The dried fibers are uniformly mixed with adhesive and additives inside this high-speed rotating blender. For lightweight MDF, MDI (Isocyanate) adhesive is commonly used because of its high bonding efficiency and curing process that doesn't require water, which is beneficial for low-density boards. Additionally, MDI is formaldehyde-free, meeting stringent environmental standards. Additives like wax can also be added for moisture resistance. The uniformity of resin application directly determines the board's mechanical properties.

Pneumatic Forming Station (Airflow Former): This is critical for forming the ultra-thin mat. The resinated fibers are distributed through forming heads and, under suction from below, are laid down evenly and smoothly onto a moving conveyor belt to form a fluffy mat of specified width and thickness. For 3mm thin board, the requirements for forming uniformity and stability are extremely high; any fluctuation can cause inconsistent final thickness or breaks.

3. Hot Pressing and Finishing Section

Continuous Press: This is the core of the production line and represents the highest level of technology. For 3mm thin board, a Continuous Flat Press or Continuous Roll Press is preferred. The formed mat enters the press where it is continuously compacted under precisely controlled temperature, pressure, and speed. The continuous press provides extremely stable linear pressure, ensuring uniform density distribution across the ultra-thin board, with thickness tolerance precisely controlled within ±0.1mm. This is an advantage unmatched by batch presses.

Cooling and Stacker: The boards exiting the press are very hot (often over 100°C) and need to be cooled to stabilize internal stresses and fully cure the resin. The cooling system uses fans and a roller conveyor to bring the boards down to near ambient temperature. A turnover device separates the boards sheet by sheet to prevent sticking.

Trim Saw and Cross-Cut Saw: The cooled boards require trimming of irregular edges and ends to achieve regular rectangular shapes and smooth edges. A combined trimming/cross-cutting system is typically used to square all four sides in one pass.

Sanding Machine: For 3mm thin board, a precision multi-head sander (e.g., 4-head or 6-head) is used. It sands the top and bottom surfaces of the board finely, eliminating thickness variation and providing a smooth, flat surface. This creates a perfect substrate for subsequent laminating, painting, printing, or direct use.

4. Auxiliary and Control Systems

Intelligent Central Control System: This system runs through the entire production line, using PLCs (Programmable Logic Controllers) and industrial computers to monitor and automatically adjust the operating parameters (e.g., temperature, pressure, speed, dosing) of each equipment unit in real-time. It is the brain behind achieving stable quality, high efficiency, and reduced energy consumption.

Dust and Exhaust Gas Treatment System: This system is responsible for collecting wood dust and process exhaust gases generated during production. It treats them through methods like baghouse filtration and chemical scrubbing to meet environmental emission standards.

|

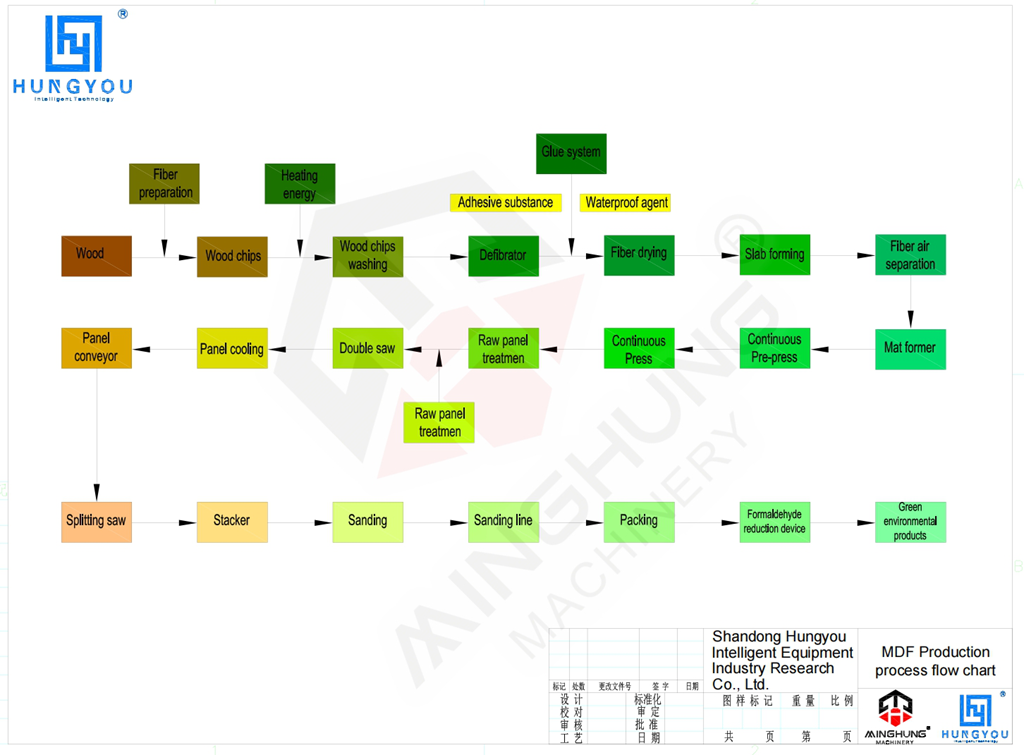

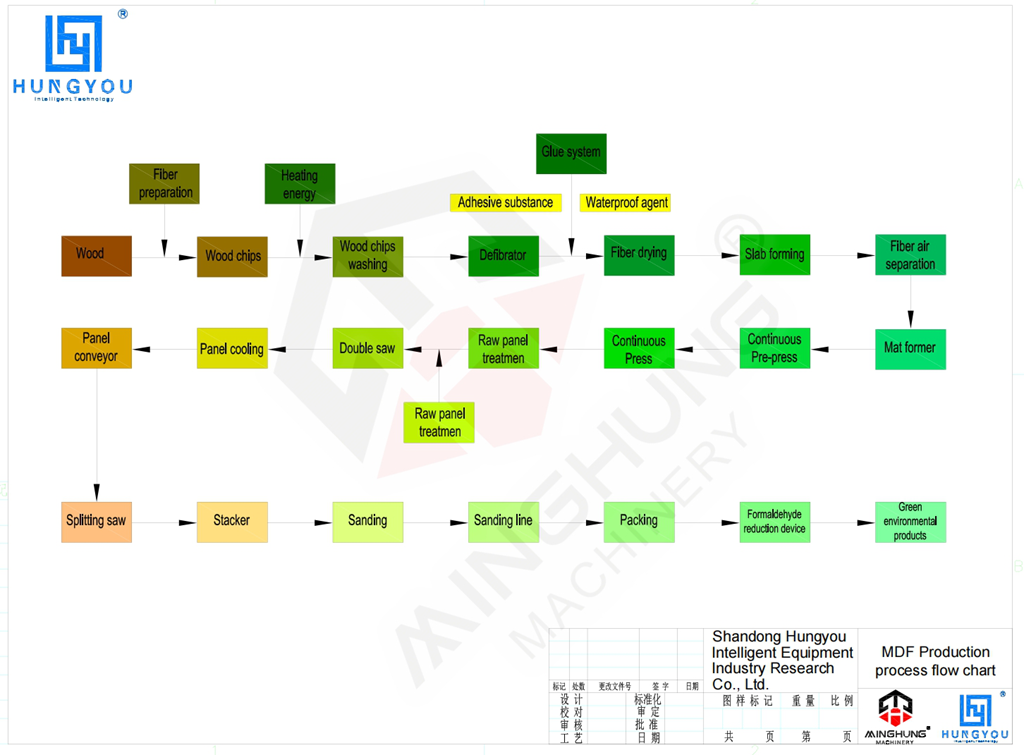

Product Process

Producing 3mm thick lightweight MDF board is a precise manufacturing process. The core objective is to minimize density (typically targeting 550-680 kg/m³, compared to standard MDF at 700-850 kg/m³) while ensuring sufficient mechanical strength. The following is a detailed step-by-step explanation of the process, highlighting key differences from standard MDF production.

Step 1: Raw Material Preparation and Fiber Production

1. Chipping: Softwood (e.g., pine) or hardwood (e.g., eucalyptus) logs, branches, or processing residues are fed into a Drum Chipper to be cut into uniform process chips.

2. Fiber Separation (Defibration): This is a critical step. The chips are fed into a Defibrator (Refiner), where they are softened by high-pressure saturated steam and then separated into individual wood fibers through the frictional force between rotating grinding discs. For lightweight MDF, the defibration parameters (e.g., steam pressure, disc gap) must be precisely controlled to produce fibers with an optimal length-to-width ratio and better strength, which is fundamental for maintaining strength at low density.

Step 2: Fiber Treatment and Resin Blending

3. Fiber Drying: The fibers exiting the defibrator have very high moisture content. They are rapidly and uniformly dried in a Pneumatic Drying System to reduce moisture content to a precise range of 8%-12%. Drying uniformity is critical.

4. Precise Resin Blending: This is the core technical step for achieving lightweight properties. The dried fibers are mixed with adhesive and additives in a Ring Blender.

Adhesive Choice: MDI (Isocyanate) adhesive is the preferred choice for three main reasons:

High Bonding Efficiency: MDI provides a much stronger bond than traditional urea-formaldehyde (UF) resin, allowing less resin to be used to meet strength requirements, directly reducing weight.

No Water Introduced: MDI is a reactive adhesive that cures without releasing water. This avoids creating excessive porosity from water evaporation within the board, which is crucial for thin and low-density boards.

Formaldehyde-Free: MDI is non-formaldehyde, making the boards inherently compliant with the strictest environmental standards (e.g., CARB NAF).

Additives: Wax is added to enhance the board's moisture resistance.

Step 3: Mat Forming and Pre-pressing

5. Uniform Mat Forming: The resinated fibers are distributed via an Airflow Forming Station. Using suction from below, the fibers are laid down evenly and smoothly onto a moving conveyor belt to form a fluffy mat. For the extreme thinness of 3mm, the requirements for forming uniformity and stability are exceptionally high; any minor fluctuation can cause inconsistent final thickness or breaks.

6. Mat Pre-pressing: The formed fluffy mat first passes through a Pre-press. This applies mild compression to remove some air and gives the mat initial strength, making it easier to handle and preventing it from being disturbed before entering the main press.

Step 4: Hot Pressing (The Most Critical Step)

7. Precision Hot Pressing: The mat enters a Continuous Flat Press or Continuous Roll Press.

Why a Continuous Press? For thin boards, a continuous press provides extremely stable, linear pressure, ensuring highly uniform density distribution along the board's length and width. This allows thickness tolerance to be precisely controlled within ±0.1mm.

Pressing Process: Under precisely controlled temperature, pressure, and conveyor speed, the resin between the fibers cures rapidly, bonding the fibers firmly together to form the final board. The settings for the pressure and temperature profiles are vital for achieving the target density and strength.

Step 5: Finishing and Processing

8. Cooling and Conditioning: The boards exiting the press are very hot (over 100°C). They are coerce cooled using a Cooling and Stacker. This not only reduces temperature but also stabilizes the internal stresses of the board to prevent warping.

9. Trimming and Cutting: The cooled boards pass through a Trim Saw and Cross-Cut Saw system to remove irregular edges, resulting in regular rectangular panels, which can be cut to specific sizes as required.

10. Precision Sanding: Finally, the boards are processed through a Multi-head Sanding Machine (e.g., 4-head or 6-head) for fine sanding. This step eliminates minor thickness variations and provides a smooth, mirror-like surface, creating a perfect substrate for subsequent laminating, painting, printing, or direct use.

Summary: Producing 3mm lightweight MDF board is a systematic project integrating precision machinery, chemical formulation, and intelligent control. Its success relies on the perfect coordination of four key pillars: high-quality fibers, MDI adhesive, precise forming, and the continuous press.

|

Application of Lightweight MDF

1. Furniture Manufacturing

This is the core application area for 3mm lightweight MDF, primarily used for non-load-bearing parts that require aesthetics and light weight.

Furniture Back Panels: Replaces traditional plywood or cardboard for the back panels of wardrobes, bookcases, and TV cabinets. It is flat and resistant to warping, lightweight for easy installation, and provides a more refined interior appearance.

Drawer Bottoms: Lighter than solid wood bottoms, making drawers easier to open and close, while providing sufficient support and resisting swelling/humidity changes.

Cabinet Door Core Material: Serves as the inner core for composite doors (e.g., thermoformed doors, wrapped doors). Its lightweight nature reduces the load on hinges, ensures smooth operation, and extends hardware life.

Furniture Liners and Shelves: Used in furniture where reducing overall weight is desired, such as liners under bed slats or lightweight shelves in display cabinets.

2. Interior Decoration and Renovation

Its smooth surface and workability make it an ideal material for the decoration industry.

Wall Cladding/Paneling: Can be directly applied to walls as decorative feature walls. The surface can be painted, laminated with PVC/film, or even printed with UV technology for custom designs.

Suspended Ceiling Tiles: Particularly suitable for creating special designs (e.g., curved ceilings) in commercial or residential spaces. The lightweight property reduces the load on the ceiling framework, enhancing safety, and it is easy to cut into shapes.

Door Skin Core Panel: Used as the internal filler material for interior doors (e.g., molded doors, composite doors), ensuring panel flatness while significantly reducing weight.

3. Construction and Display Industries

Building Substrate: Used for constructing lightweight partition walls or as an underlayment for flooring, providing levelling, sound insulation, and thermal insulation.

Exhibition and Display: An ideal material for exhibition panel systems, standard booth walls, sign backings, and promotional display stands. Light weight translates to lower transport and setup costs, facilitating reuse.

Commercial Props: Used for product display stands, counters, and temporary partitions in shops and malls. The surface can be finished in various ways to achieve the desired visual effect.

4. Electronics and Packaging

Electronic Equipment Padding: Used for internal support and cushioning in high-end electronic products (e.g., speakers, instruments), meeting requirements for both structural strength and light weight.

High-End Gift Packaging: Used for making inner liners and structural boxes for premium gift boxes, jewelry cases, and wine boxes, offering better texture and a more upscale feel than standard cardboard.

5. Creative DIY and Crafts

Due to its ease of cutting, engraving, and painting, it is popular among DIY enthusiasts and crafters for making models, photo frame backs, creative home decor items, etc.

|

Comment & FAQ

Q:What can you purchase from us?

A:Particle board production line, directional particle board production line, medium/high fiber board production line, hot press, preforming press machine, plywood production line, automatic production line for hot press, veneer dryer, hot press, cold press machine and other woodworking machinery.

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

Q:How is your quality?

A:As an experienced manufacturer, the quality of our machines can be guaranteed and we have supplied our products to thousands of customers all over the world.

Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

|

Photos of delivery

|

Certifications

|

Customer group photo