Semi-Auto Compact Plywood Macking Machine Line

Main Equipment Functions and Parameters

The line is designed for small-scale investment, with equipment selected for economic efficiency and practicality while ensuring core functionalities.

Equipment Name | Main Function | Key Parameters & Features |

1. Hydraulic Single/Double Spindle Peeler | Peels conditioned log blocks into continuous, uniform-thickness veneer ribbons. The core component determining veneer quality and yield. | Peeling Diameter: Φ150mm - Φ600mm (Common range) |

|

| Peeling Length: 1300mm, 1500mm, 1800mm, etc. (Customizable) |

|

| Veneer Thickness: 1.0mm - 4.0mm (Adjustable) |

|

| Drive Power: 15kW - 30kW (Model dependent) |

|

| Features: Hydraulic clamping and feed ensure smooth operation; Robust construction for continuous duty; Choice of single or double spindle based on budget. |

|

2. Roller Type Veneer Dryer | Rapidly dries wet veneer to a moisture content of 8%-12% for storage and subsequent gluing. | Working Length: 15m - 25m (Depending on capacity) |

|

| Drying Temp.: 80℃ - 150℃(Adjustable) |

|

| Heat Source: Steam, Thermal Oil, or Electric |

|

| Features: Multi-layer roller transport for even drying; Equipped with fans and dehumidification for high efficiency; Compact structure with a relatively small footprint. |

|

3. Gluing & Layup Station | Applies adhesive to dried veneer and manually assembles them into a cross-banded mat (adjacent layers perpendicular). | Glue Spreader Type: Double or Four-Roller Spreader |

|

| Working Width: 1300mm, 1500mm, etc. (Matches peeling length) |

|

| Features: Manual feeding and layup offer flexibility for producing panels of various specs and plies; Low equipment cost and easy maintenance. |

|

4. Small Multi-opening Hot Press | Applies heat and pressure to the assembled mat, curing the adhesive to form strong plywood. | Number of Openings: 10 - 20 (Common) |

|

| Platen Size: 4'x8' (1220x2440mm) or Custom |

|

| Working Pressure: 16MPa - 25MPa |

|

| Heat Source: Steam, Thermal Oil, or Electric |

|

| Control: PLC-controlled, auto/manual pressure cycles |

|

| Features: Optimized for small lines with moderate tonnage and openings; Automation meets core process needs at a controllable investment. |

|

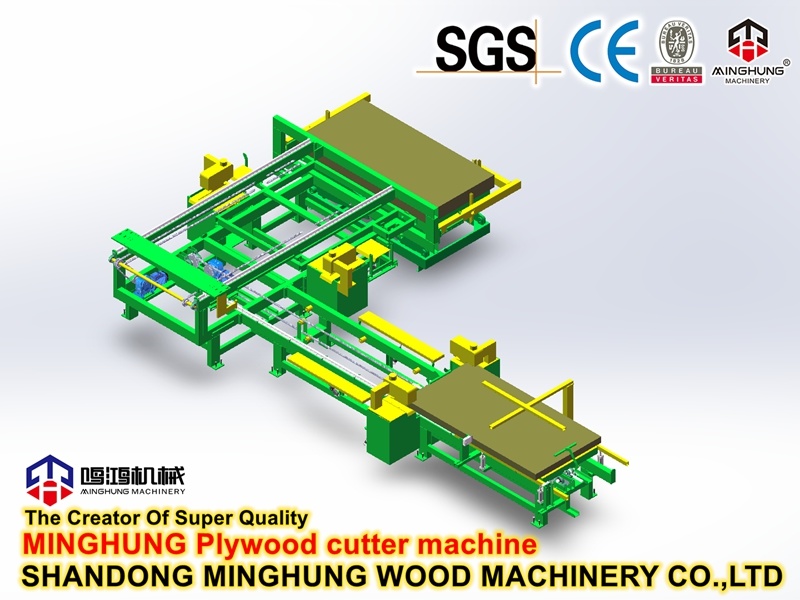

5. Auxiliary Equipment | Performs finishing operations to enhance final product quality. | Edge Trimmer: Sizes pressed rough panels to standard dimensions. |

|

| Sander: Single or Double-sided sander for calibrating thickness and surface finishing. |

|

| Hydraulic Lift Table/Trolley: Aids in loading/unloading mats and handling semi-finished products. |

|

|

The process is clear and streamlined. Core stages are equipment-driven, while some handling and layup steps involve manual operation, achieving a balance between efficiency and flexibility.

1. Raw Material Prep: Logs are crosscut and conditioned (steamed/boiled as per wood species) for softening.

2. Peeling: Conditioned log blocks are fed into the peeler and rotated into continuous veneer ribbons of set thickness.

3. Drying & Clipping: Wet veneer ribbons enter the roller dryer. Once dried, they are manually or semi-automatically clipped to size.

4. Gluing & Layup (Semi-Auto Core): Workers feed dried veneer through the glue spreader. The coated veneer sheets are then manually laid up on the station into a cross-banded mat (e.g., 7-ply, 9-ply, 11-ply) following the perpendicular grain direction rule.

5. Pre-pressing & Hot Pressing: The assembled mat may undergo cold pre-pressing for initial shaping before being loaded into the hot press. Curing occurs under set temperature, pressure, and time parameters.

6. Finishing: Pressed panels are cooled, then sequentially processed by the edge trimmer for sizing and the sander for surface finishing. Final steps include inspection, grading, and packaging for storage.

Core Advantages of This Production Line

Compared to fully automatic large-scale lines, this semi-automatic small-scale line offers distinct, irreplaceable advantages for specific markets and applications:

1. Low Initial Investment & Entry Barrier: The total equipment cost is significantly lower than fully automatic lines, drastically reducing the capital barrier. This allows small entrepreneurs, family businesses, and regional investors to easily enter the plywood manufacturing sector.

2. High Flexibility & Adaptability: The semi-automatic mode is ideal for small-batch, multi-variety production orders. It allows quick changeovers to produce plywood of different thicknesses, plies, and wood species, easily responding to customized demands and regional market fluctuations.

3. Lower Operational & Maintenance Costs: The relatively simple equipment design requires moderately skilled operators and allows for easy daily maintenance. Operational costs (energy, labor) are controllable, and it does not rely on complex automation systems or expensive spare parts.

4. Space-Saving & Quick Setup: The production line has a compact layout, requiring less factory space and ceiling height. Equipment installation and commissioning are quick, enabling rapid deployment and production start-up to seize market opportunities.

5. Fast ROI & Controllable Risk: Due to the smaller total investment, achieving a return on investment within a relatively short timeframe is more feasible under stable market demand, significantly lowering business risk.

Compared to fully automatic large-scale lines, this setup requires a much lower initial investment and offers greater operational flexibility. It is the perfect entry-level choice for venturing into the plywood manufacturing industry or for small-batch, multi-variety production.

We provide installation guidance for key equipment and production training to ensure our customers can start up quickly and smoothly.

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Why choose us?

We are not only equipment suppliers, but also your reliable business partners. We offer a turnkey solution covering factory planning, equipment installation, commissioning, personnel training and after-sales support. Choosing us means choosing quality, innovation and continuous support.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com