Ⅰ. OSB (Oriented Strand Board)

1. Definition & Structure

OSB is an engineered wood panel made from directionally aligned wood strands, bonded with resin under heat and pressure.

Key features:

- 3-Layer Orientation: Surface strands aligned longitudinally (bending strength), core strands cross-oriented (dimensional stability);

- Eco-Materials: Uses fast-growing timber (e.g., poplar, pine) or recycled wood;

- Advanced Resins: Typically PMDI (Polymeric Methylene Diphenyl Diisocyanate), meeting EN 300 waterproof standards.

2. Performance Advantages

Property | Value/Description |

Mechanical Strength | MOR ≥22 MPa (exceeds plywood) |

Moisture Resistance | 24h Thickness Swelling <15% (EN 317) |

Emission Class | Formaldehyde Release ≤0.03 ppm (CARB P2) |

Applications | Structural sheathing, container flooring, furniture substrates |

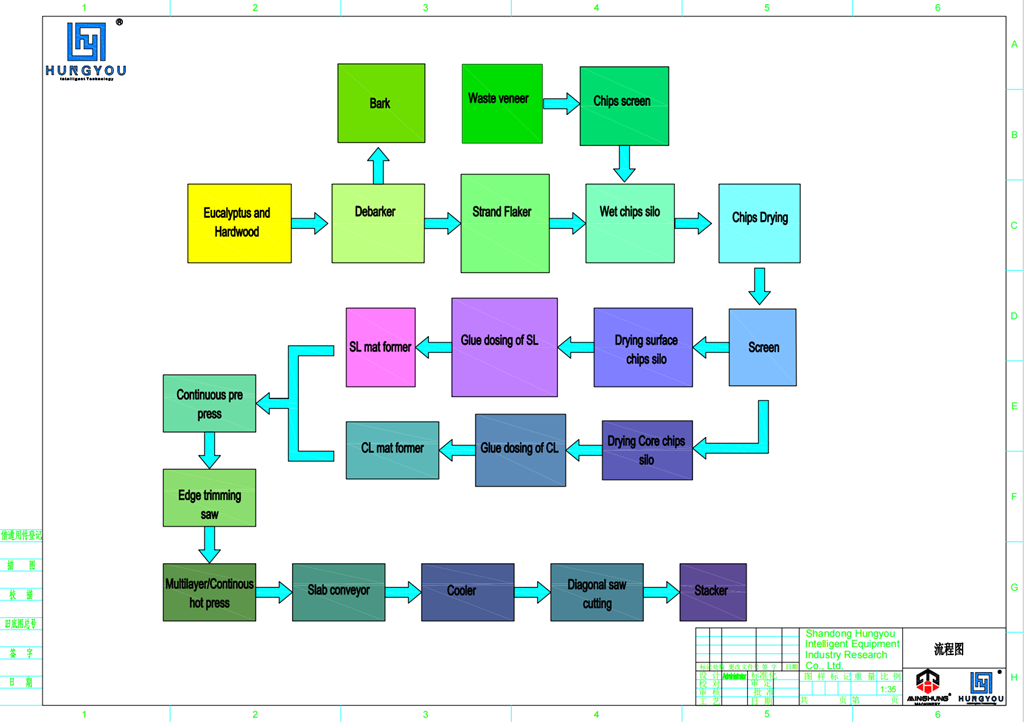

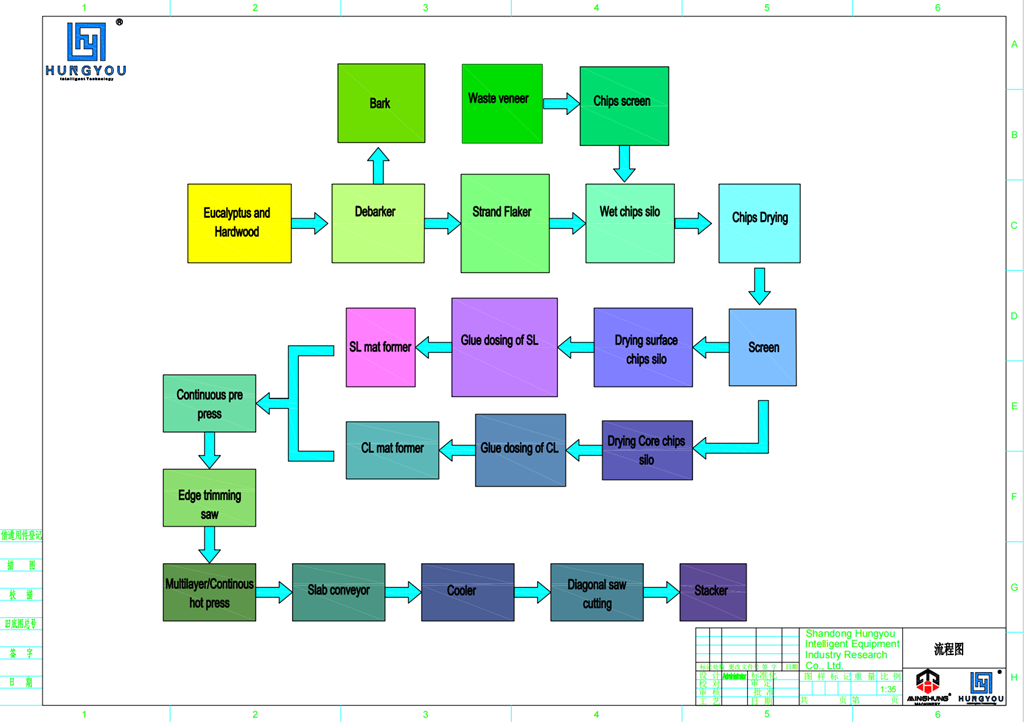

3. Production Process

Strand Preparation: Wood cut into 50–100 mm long × 10–30 mm wide strands;

Resin Application: Face strands coated with 8–12% PMDI, core strands with 3–5% UF/MUF resin;

Oriented Forming: Mechanical/pneumatic aligners create cross-oriented layers;

Continuous Pressing: Cured under high pressure (>5 MPa) and temperature (200–220°C).

II. Continuous Flat-Platen Hot Press Technology

1. Core Function

As the heart of OSB lines, continuous presses enable high-speed (>1,200 mm/s), large-format (up to 4.8 m wide) production, eliminating bottlenecks of batch-type multi-opening presses.

2. Critical Subsystems

Steel Belt Conveyance: Heat-resistant alloy belts (1.2–1.8 mm thick) run under constant tension;

Zoned Hydraulics: 12 independent pressure zones (5–40 MPa adjustable) for gradient control (gas release → high-pressure bonding → thickness calibration);

Thermal Oil System: Oil circulates in heated platens with ±1.5℃ precision for uniform curing;

Thickness Control: Laser sensors monitor board thickness, dynamically adjusting pressure (±0.05 mm accuracy).

3. Technological Innovations

Continuous Efficiency: 300% higher output vs. batch presses, supporting 24/7 operation;

Energy Optimization: Waste heat recovery cuts steam usage by 35%, servo-hydraulics save >25% power;

Smart Control: PLC-based PID algorithms compensate for belt deformation, ensuring density uniformity (deviation <3%).

4. Industrial Value

Addresses OSB production imperatives:

Rapid high-pressure curing of PMDI resin (<3 min press time);

Precise control of interlayer stresses in oriented structures;

Flexible production for varying densities (550–750 kg/m³).

5.Working principle and process flow

(1) Directed paving and pre-pressing

Directed paving:

OSB wood chips are divided into surface layer (longitudinally arranged) and core layer (transversely arranged), and are oriented by a special paving machine (such as a mechanical directional head or airflow paving system). The length of the surface layer wood chips is usually 50-100mm, and the core layer wood chips are shorter (20-50mm).

Pre-pressing and shaping:

The paved slab enters the pre-pressing machine (pressure 0.5-1.5MPa), and the air is removed and the direction of the wood chips is initially fixed by mechanical roller pressing or high-frequency pre-pressing to prevent the structure from loosening during the subsequent hot pressing process.

(2) Continuous hot pressing stage

High pressure zone (initial curing):

Temperature 210–230℃, pressure 3.0–5.0MPa, quickly close the slab and activate the adhesive (usually phenolic resin or MDI adhesive), and the surface wood shavings directional structure is initially cured.

Medium pressure zone (plasticization balance):

Temperature 200–220℃, pressure 2.0–3.5MPa, maintain full penetration of the core layer adhesive, and balance the curing rate of the inner and outer layers.

Low pressure zone (setting and stress release):

Temperature 180–200℃, pressure 1.0–2.0MPa, control the final thickness and release internal stress to avoid board warping.

(3) Cooling and post-processing

Cooling section:

The pressed sheet is cooled to below 50°C by a circulating water cooling system to stabilize the sheet size.

Cutting and sanding:

The sheet is cut into standard sheets using a high-speed sawing system, and the surface flatness is adjusted using a sander.

Ⅲ.12-Zone Independent Hydraulic System

1. Core System Design

The 12-zone independent hydraulic system is the core of OSB (Oriented Strand Board) high-pressure continuous presses. It adopts a dedicated circuit design (each zone’s actuator is supplied by a separate control valve), enabling independent pressure and flow regulation across all 12 pressing zones. Each zone integrates high-precision proportional valves and pressure sensors for closed-loop control of platen pressure and cylinder displacement, meeting diverse requirements such as exhaust, thickness calibration, and curing pressure during different pressing stages.

2. Operational Principles

2.1 Zone-Specific Control: Each hydraulic zone corresponds to a longitudinal section of the press.

For example:

Zones 1–3 (infeed) apply low pressure to facilitate gas escape;

Zones 4–9 (middle) deliver high pressure for bonding;

Zones 10–12 (outfeed) reduce pressure to stabilize board formation.

2.2 Pressure-Displacement Synchronization: Proportional valves dynamically adjust cylinder pressure while displacement sensors monitor platen positions. PID algorithms achieve millimeter-level multi-cylinder synchronization, eliminating thickness deviations.

2.3 Fault Isolation: The dedicated circuit design isolates zone failures, allowing uninterrupted operation in non-affected zones during maintenance.

3. Technical Advantages

High Adaptability: Supports flexible production of 12 mm to 40 mm OSB, with pressure adjustability of 5–40 MPa.

Energy Efficiency: Independent zones supply oil on-demand, reducing energy consumption by ~25% versus serial systems and improving response speed by 40%.

Stability Assurance: System simulations (via AMESim/Matlab) optimize transfer function parameters, suppressing pressure fluctuations and maintaining platen deformation <0.1 mm during continuous operation.

Our company not only specializes in the production of directional particleboard (OSB) lines, but also manufactures complete production lines for medium-density fiberboard (MDF), high-density fiberboard (HDF), particleboard (PB), and laminated super-strong particleboard (LSB).

If necessary, please feel free to contact us at any time.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com