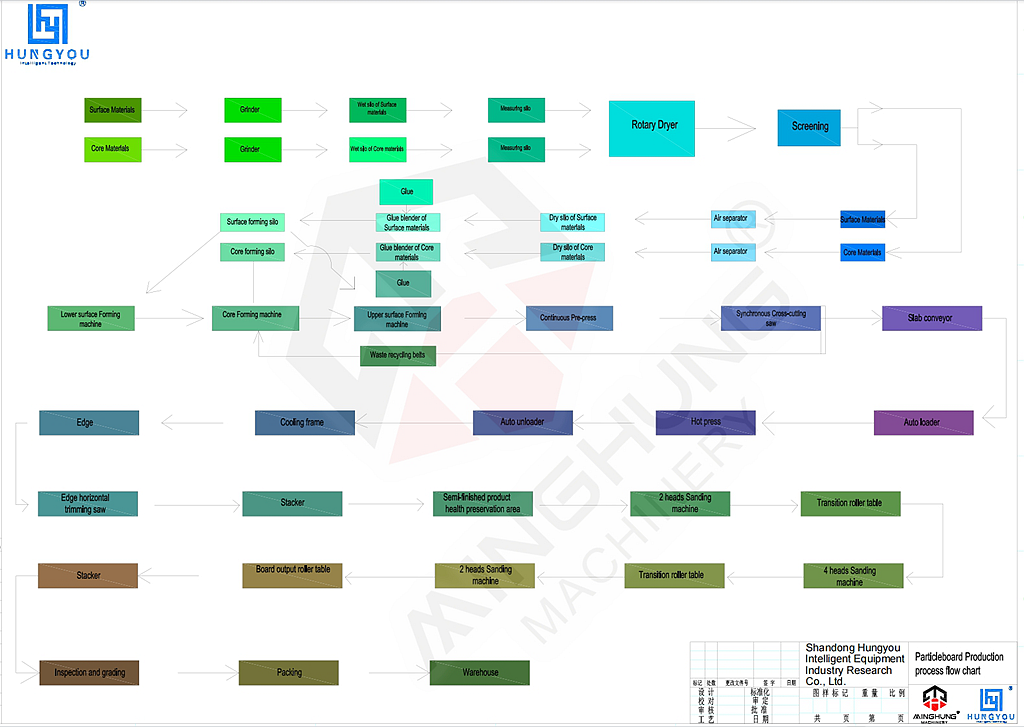

Ⅰ.Particleboard Production Line Process

1. Raw Material Processing

Wood materials (logs, branches, recycled wood) are chipped by a drum chipper, then refined through a hammer mill to form uniform particles sized 0.2–2mm. Wood utilization rate ≥95%.

2. Drying

Wet particles enter a triple-pass rotary dryer using direct natural gas heating. Moisture content is rapidly reduced from 40–60% to 3–5% (±0.5% accuracy) at 180–220°C, with a drying capacity of 18 tons water/hour.

3. Screening and Classification

Dried particles are graded via multi-deck screens:

- Surface layer: <0.5mm fines (for high-density surfaces)

- Core layer: 0.5–2mm coarse particles (ensuring core strength)

- Oversized particles: Returned to recycling system

4. Resin Application System

Classified particles enter a high-speed ring blender:

- Surface fines: Coated with 12–14% melamine-modified urea-formaldehyde (MUF) resin

- Core particles: Coated with 8–10% MDI resin

- Resin application accuracy: ±5g/m², processing speed: 12 tons/minute

5. Mat Forming

Mechanical-pneumatic blending forming system:

- Bottom layer: 0.3mm fines (density ≥750kg/m³)

- Core layer: 1.5mm coarse particles (density 650kg/m³)

- Surface layer: 0.2mm super-fines (density ≥780kg/m³)

Creates three-layer graded-density structure at 120 meters/minute.

6. Pre-pressing

Mat passes through a double-roller pre-press:

- 1.5MPa pressure, compressed to 70% target thickness

- Eliminates fluffiness and prevents mat disruption

7. Continuous Flat Pressing (Core Stage)

Mat enters dual-steel-belt continuous press:

- Hot Pressing: Belt temperature 220–250°C, 40 pressure zones (entry: 4.0MPa → exit: 1.5MPa)

- Precise Dwell Control: Automatic speed adjustment by thickness (6mm: 60m/min; 25mm: 9m/min)

- Real-time Thickness Control: Laser measurement + hydraulic pads ensure ±0.1mm tolerance

8. Cooling

Hot boards enter roller-type cooling station:

- Forced-air cooling reduces temperature from 180°C to 45°C in 10 minutes

- Eliminates internal stresses and prevents warping

9. Sawing

High-speed cross-cut and trim saws:

- Cut to standard dimensions (2440×1220mm)

- Edge trims recycled to raw material system

10. Stacking and Curing

Automated stacking followed by 24–48hr ambient conditioning:

- Ensures complete resin curing and stress release

11. Sanding

Four-head double-side calibrating sander:

- CCD thickness detection + adaptive grinding

- Final tolerance ±0.1mm, surface roughness Ra≤5μm

12. Grading and Packaging

Automated inspection by quality grade:

- Grade A: Flawless, direct film wrapping

- Grade B/C: Marked for secondary processing

- Finished goods stored for shipment

II. Core Production Components

Component | High-Capacity Specification | Feature Highlights | Function |

Chipper System | Drum chipper + Hammer mill | Wood utilization rate ≥95%, particle size of crushed materials 0.2-2mm controllable | 120 BDt/h output |

Dryer | Triple-pass rotary (gas-fired) | Gas direct heating, outlet moisture content error ±0.5% | 18 t/h H₂O removal |

Resin Blender | High-speed ring type | Atomized glue spraying + dynamic weighing, glue application accuracy ±5g/m² | 12 t/min @ ±5g/m² |

Forming Station | Mechanical-airflow composite paving head | Forming a gradient density structure, fine material on the surface/coarse material in the core | 3-layer graded density;Paving speed: 120m/min |

Continuous Press | Dual-steel-belt system (see below) |

| Production core |

Cooling Conveyor | Forced-air spiral type |

| 10-min cooling cycle |

Sanding Line | 4-head double-side sander | CCD thickness detection + adaptive sanding, tolerance ±0.1mm | 150 m/min throughput |

Chipper

Dryer

Resin Blender

Forming machine

Continuous Press

Sanding machine

III. Continuous Flat Press: Technology & Capacity

Core Technical Features

1. Dual Steel Belts

- Material: Hastelloy® with nano-ceramic coating

- Thickness: 1.8mm

- Service life: ≥5 years

2. Heating System

- 40-zone thermal oil circulation

- Temperature control: ±0.3°C (200–250°C range)

3. Hydraulic Pressure

- 500bar servo-controlled system

- Response time: ≤50ms

4. Thickness Control

- Laser measurement + hydraulic adjustment

- Thickness changeover: 90 sec (18→6mm)

Ⅳ.Continuous Press Core Capacity Data (2.5m width line example)

Actual output capacity under different thicknesses

Thickness | Line Speed | Output per Minute | Annual Capacity (10k m³) |

6mm | 60 m/min | 0.9 m³ | 38.9 |

12mm | 30 m/min | 0.9 m³ | 38.9 |

18mm | 18 m/min | 0.81 m³ | 35 |

25mm | 9 m/min | 0.56 m³ | 24.3 |

Ⅴ. Key technological breakthroughs for high production capacity

1. Press inlet acceleration technology

- Paving-hot pressing synchronous control system, slab gap shortened to 15cm (traditional ≥50cm)

- Effectively improve time utilization by 12%

2. Near infrared online moisture content monitoring

- Real-time control of wood shavings moisture content after sizing (target value 9.5±0.3%)

- Reduce hot press steam release time by 15%

3. Intelligent operation and maintenance system for presses

- Ultrasonic monitoring of steel belt stress, reducing the unexpected downtime rate to <2%

Customize Your Line! Full-service solution from layout design to production optimization. Request a tailored proposal now.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com