I. Core Customization Principles

1.1 Modular Mechanical Architecture

Width-Adjustable Units: Standard 500mm modules assemble via hydraulic locking pins (±0.05mm precision).

Seamless Platen Joints: Laser welding + plasma polishing (Ra≤0.8μm).

1.2 Adaptive Hydraulic System

Width Increase | Additional Cylinders | Uniformity Control |

Per 1 meter | 4–6 cylinders | Edge pressure +15% + closed-loop feedback |

>3.5 meters | 8 cylinders/meter | Secondary pressure valves (<50ms response) |

1.3 Thermal Management

Zoned Heating:

Center: 180–220°C

Edges: +10–20°C compensation

Expansion Control:

Pre-cambered platens (0.1–0.3mm/m arch)

Low-expansion cast iron frames (CTE 1.2×10⁻⁶/K)

2. Key Technologies

2.1 Edge Effect Elimination

Physical Solutions:

Double-density heating tubes (edge: ≤80mm spacing)

Extendable platen wings (hydraulic-driven, +100mm)

Control Systems:

Infrared thermography (0.5°C resolution) → Dynamic edge temperature adjustment

Pressure sensor array (1 sensor/200mm) → Adaptive pressure compensation

2.2 Dynamic Rigidity Assurance

Structural Enhancements:

Component | Wide-version Reinforcement |

Main Frame | Box steel +40% internal ribs |

Platen Supports | Tungsten carbide-coated guides |

Vibration Suppression:

Active damping (0–50Hz frequency range)

Belt tension control (±1% precision)

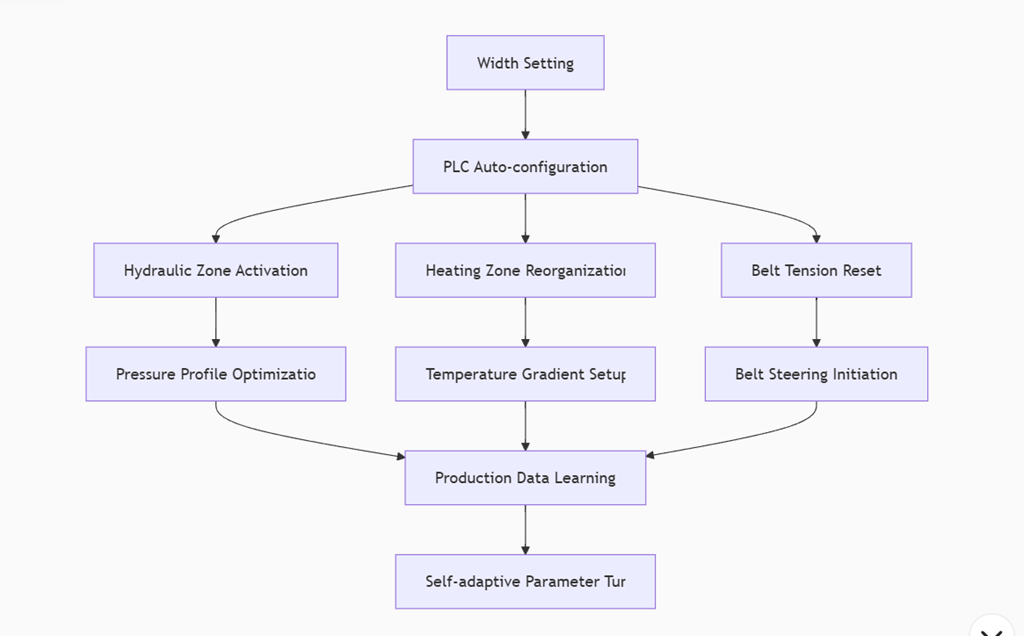

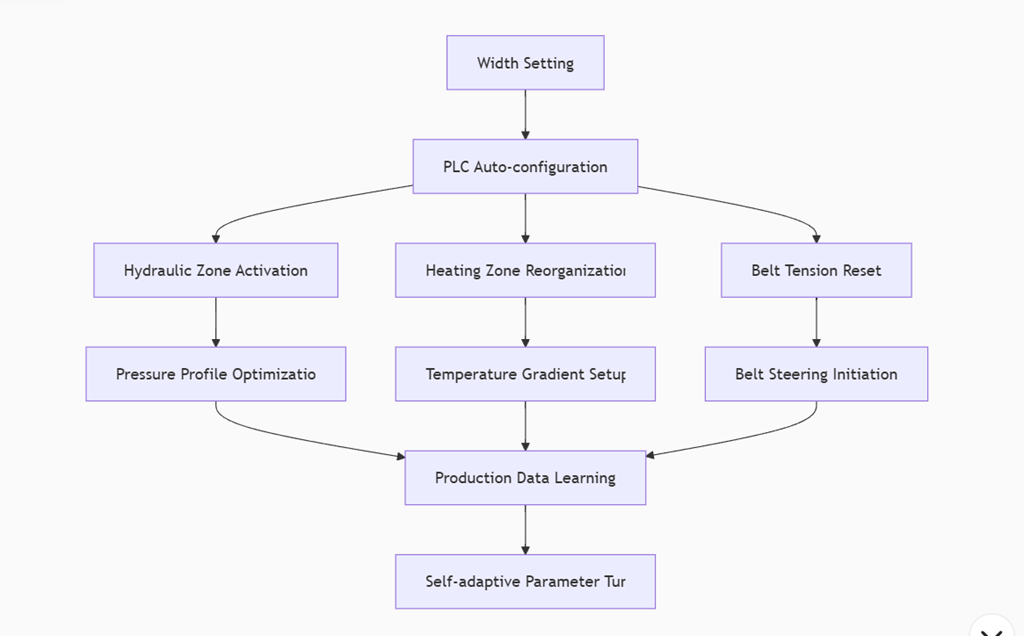

2.3 Intelligent Control Logic

3. Customization Validation

3.1 Performance Comparison (2.8m vs 4.2m Press)

Metric | 2.8m Press | 4.2m Press | Technical Differentiation |

Density Variation | ±3% | ±4.5% | +12 edge cylinders |

Thickness Tolerance | ±0.15mm | ±0.22mm | Reinforced frame + laser gauges |

Warpage | ≤0.8mm/m | ≤1.2mm/m | Edge temp control ±1.5°C |

Capacity Increase | Baseline | 0.5 | Max. belt speed 110m/min |

3.2 Implementation Cases

Narrow-width Line (1.2m):

Application: R&D lab/specialty boards

Key tech: Quick-change system (45-min width switch)

Extra-wide Line (4.5m):

Application: Structural panels for construction

Innovation: Split platens (10mm expansion gap)

4. Customization Workflow

Requirement Analysis --> Feasibility Study --> Modular Configuration --> Critical Component Upgrade --> Control System Programming --> F[Factory Pre-assembly --> On-site Commissioning --> Process Parameter Tuning --> Production Acceptance