IV. Specification Characteristics of "Super-Wide" Fiberboard Continuous Presses

"Super-wide" denotes an even higher specification than "wide," representing the pinnacle of current continuous press technology, primarily used for building world-scale giant fiberboard production lines.

"Super-Wide" Definition: Typically refers to continuous presses with an effective pressing width exceeding 3.0m (9.8'), reaching 3.5m (11.5'), 4.0m (13.1'), or even larger.

Core Specification Characteristics:

1. Massive Effective Width: The most prominent feature. Common super-wide specifications include 3.5m, 3.8m, 4.0m, 4.2m, 4.8m (16'), etc. A 4.8m wide press can produce rough panels close to 4.6m wide.

2. Extra-Long Press Length: To match the massive width and achieve high capacity/thick board production, super-wide presses are often significantly longer, reaching 60 meters or even over 70 meters. This provides sufficient pressing and heating distance.

3. Very High Design Capacity: Super-wide presses are built for extreme economies of scale. Single-line annual design capacity is typically over 700,000 m³, often exceeding 1 million m³. Daily output can reach 3000 m³ or higher. One such line can match the output of multiple traditional factories.

4. Advanced Steel Belt Technology:

Massive Size & Thickness: Belts must match the press width and are over 100 meters long (forming the loop). Requirements for thickness, strength, stiffness, and thermal conductivity are extremely high.

Precision Tensioning & Tracking Systems: Ensuring absolute stability, flatness, and alignment for such massive, high-speed belts in both length and width directions is a major challenge, demanding highly complex, sensitive, and powerful hydraulic or electromechanical control systems.

Special Surface Treatments: Ensure smooth mat release and panel surface quality.

5. Complex & Massive Heating Platen System:

Large Quantity: More pressure/temperature zones along the length (potentially over 100).

Oversized Dimensions: Individual platens must cover the entire effective width, posing significant manufacturing challenges.

Precise Zonal Temperature Control: Achieving highly uniform and independently controllable temperature profiles across such vast width and length is a core technical challenge.

High-Efficiency Heat Transfer Fluid System: Requires very high flow rates of thermal oil (or steam) circulation to ensure stable heat supply and transfer efficiency.

6. Ultra-Powerful Hydraulic System:

Enormous Total Closing Force: Required to generate tens of thousands of tonnes (even exceeding 100,000 tonnes) of total force to compress the mat across the full width.

Finer Zonal Pressure Control: More zones demand higher precision, independence, and faster response in controlling pressure for each zone to ensure absolute density uniformity across the super-wide panel. This is a severe test for hydraulic system design, component precision, and control systems.

7. State-of-the-Art Automation & Control System:

Must process vast amounts of sensor data (temperature, pressure, position, speed, thickness, etc.).

Enables coordinated control of the entire massive system (forming, press, sawing, cooling, sanding, etc.).

Employs advanced model predictive control (MPC) and AI algorithms to optimize process parameters (temperature/pressure profiles), ensuring ultimate product quality stability at super-scale production.

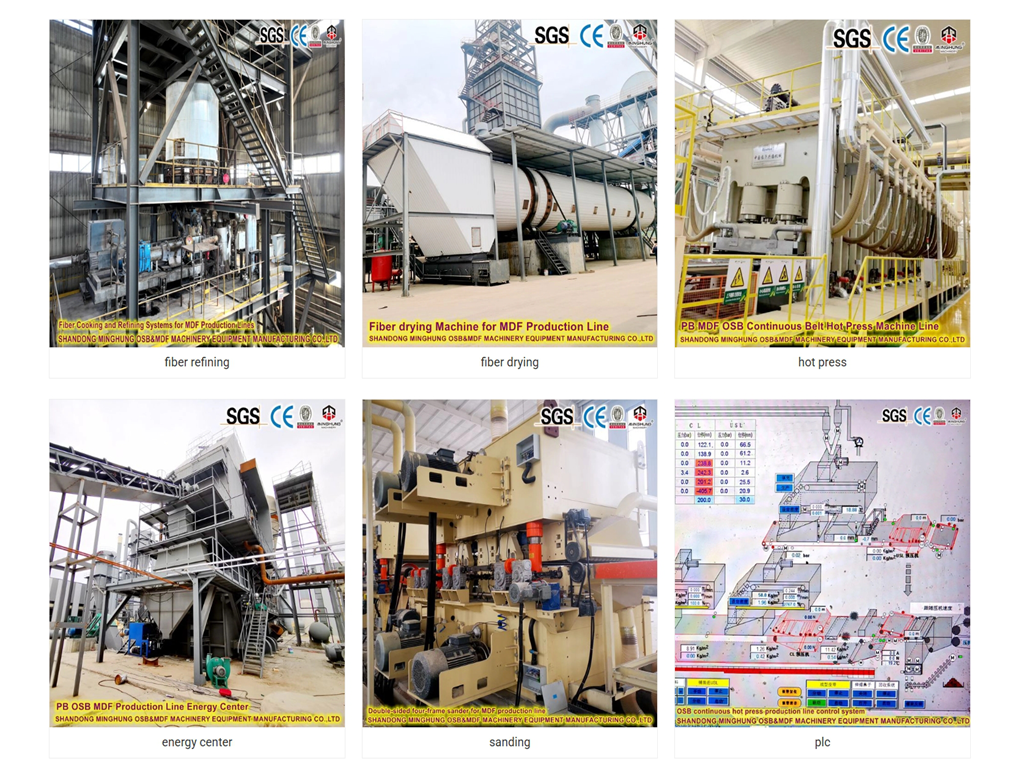

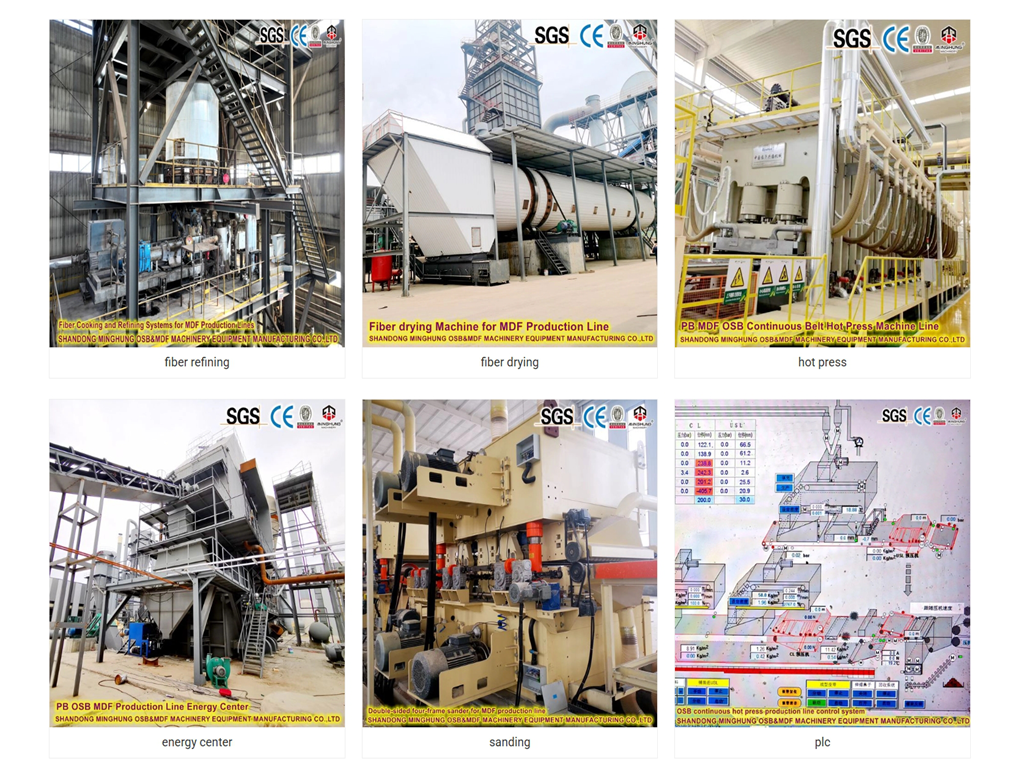

8. Matched Upstream & Downstream Equipment:

High-Capacity Fiber Preparation: Chipping, refining, drying, and blending systems must match the press capacity.

Super-Wide Forming Station: Capable of precise, uniform fiber distribution across the ultra-wide mat, especially critical for surface/fine and core/coarse layer structures.

Giant Finishing Equipment: E.g., super-wide flying saws, large cooling star coolers/racks, super-wide sanders (often 4-head or more), and massive stacking/packaging systems.

9. Plant & Infrastructure Requirements: Demands enormous factory space (height, span, length), very high electrical power supply (tens of Megawatts), large-capacity thermal oil heating systems, and corresponding logistics (raw material intake, finished product dispatch).