Automatic Veneer Drying Machine Line: A Comprehensive Solution for Efficient Veneer Drying

Veneer drying is a critical process in the woodworking industry, as it directly impacts the quality and durability of the final products. To ensure optimal results, investing in a reliable and efficient veneer drying machine line is essential. In this article, we will explore the various types and configurations of automatic veneer drying machines, highlighting their features and benefits.

Mesh Veneer Drying Machine: The Perfect Balance of Airflow and Support

One of the most popular options in the market is the mesh veneer drying machine. This type of machine utilizes a mesh conveyor belt to transport the veneer sheets through the drying chamber. The mesh design allows for excellent airflow, ensuring uniform drying throughout the entire veneer stack. Additionally, the mesh provides adequate support to prevent any warping or deformation of the veneer during the drying process.

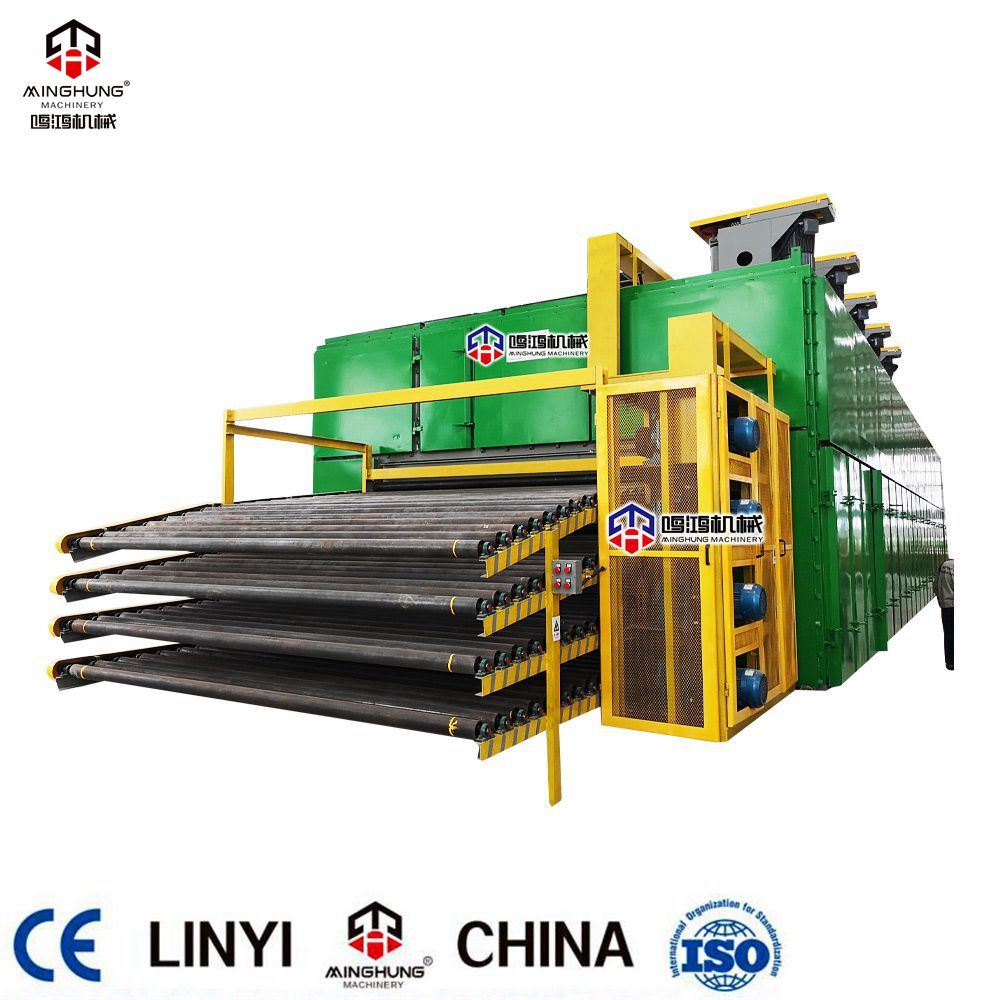

Roller Veneer Drying Machine: Ideal for High-Volume Production

For woodworking businesses with high production demands, a roller veneer drying machine is the perfect choice. This machine utilizes a series of rollers to transport the veneer sheets through the drying chamber. The rollers ensure smooth and continuous movement, allowing for efficient drying of large quantities of veneer. With multiple layers available, ranging from 1 to 6 layers, these machines can handle a wide range of production volumes.

Wire Veneer Dryer: Precision Drying for Thin Veneers

When it comes to drying thin veneers, a wire veneer dryer is the go-to option. This machine utilizes a series of parallel wires to support the veneer sheets during the drying process. The wires allow for maximum airflow, ensuring quick and precise drying of the thin veneers. With various width options available, including 2800MM, 3200MM, 4000MM, 4500MM, 4800MM, and 5000MM, these machines can accommodate different sizes of veneer sheets.

Versatility and Customization: The Key Features of Automatic Veneer Drying Machine Lines

What sets automatic veneer drying machine lines apart is their versatility and customization options. These machines can be configured with multiple layers, allowing for simultaneous drying of different veneer stacks. This feature significantly improves production efficiency and reduces overall drying time. Additionally, the width options available ensure compatibility with various veneer sheet sizes, catering to the specific needs of different woodworking businesses.

In conclusion, investing in an automatic veneer drying machine line is crucial for woodworking businesses aiming to achieve efficient and high-quality veneer drying. Whether you opt for a mesh veneer drying machine, roller veneer drying machine, or wire veneer dryer, each type offers unique benefits tailored to specific requirements. With customizable options and various width choices, these machines provide a comprehensive solution for all your veneer drying needs.

Whatsapp: +8618769900191 +8615805493072 +8615589105786