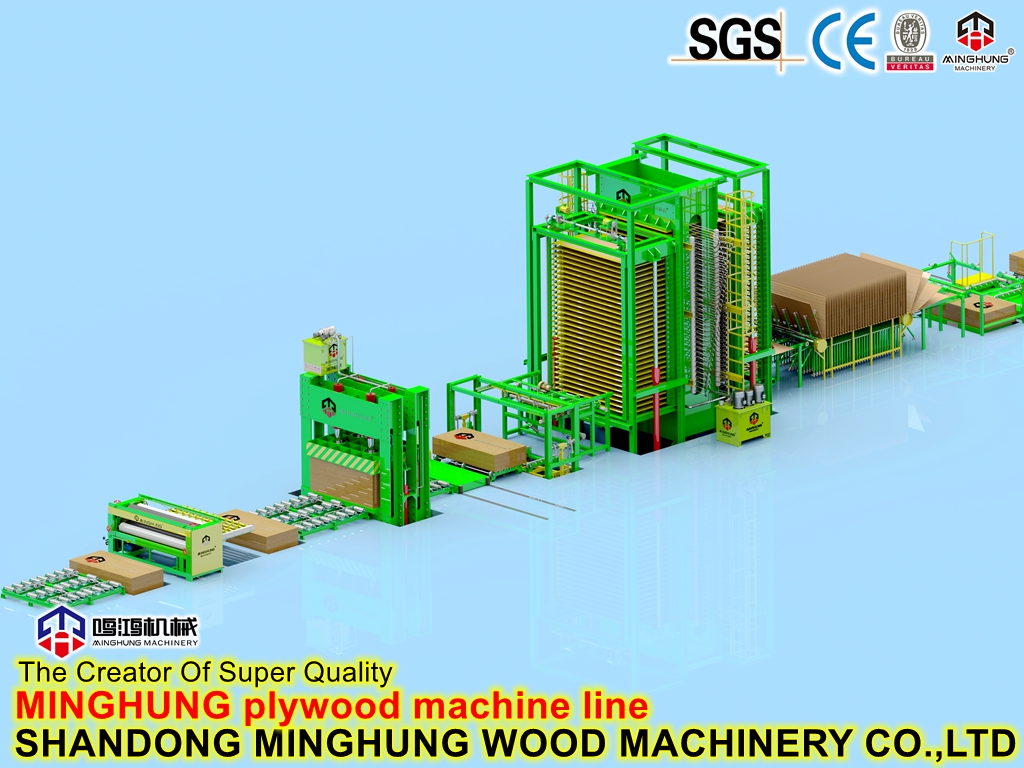

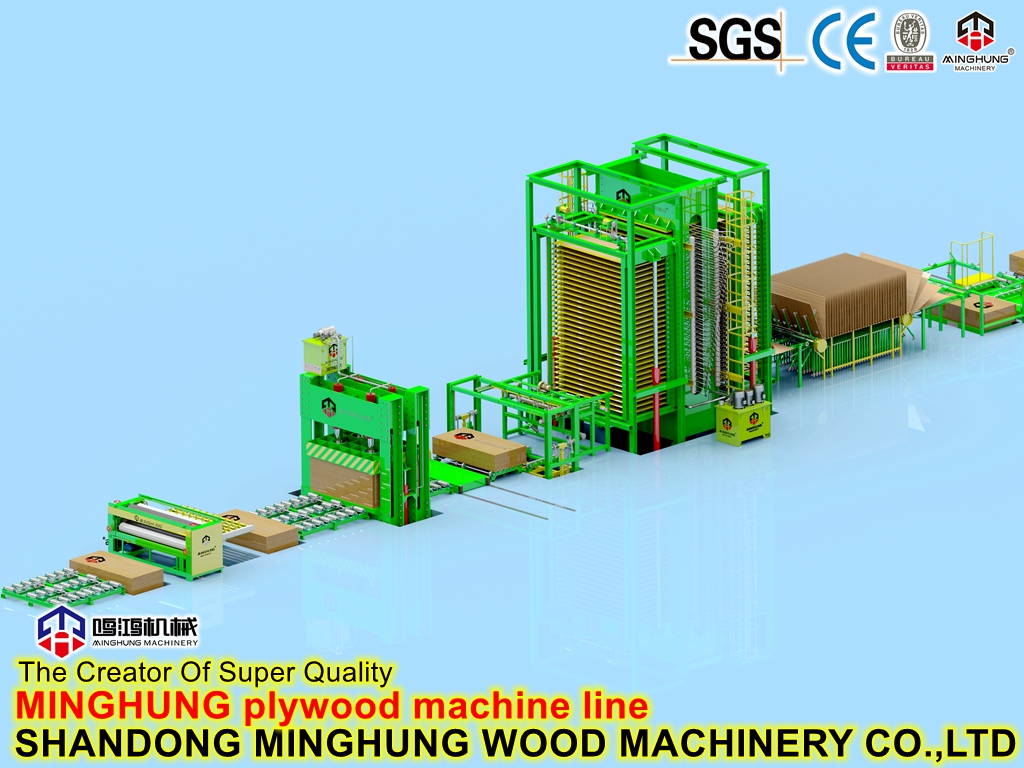

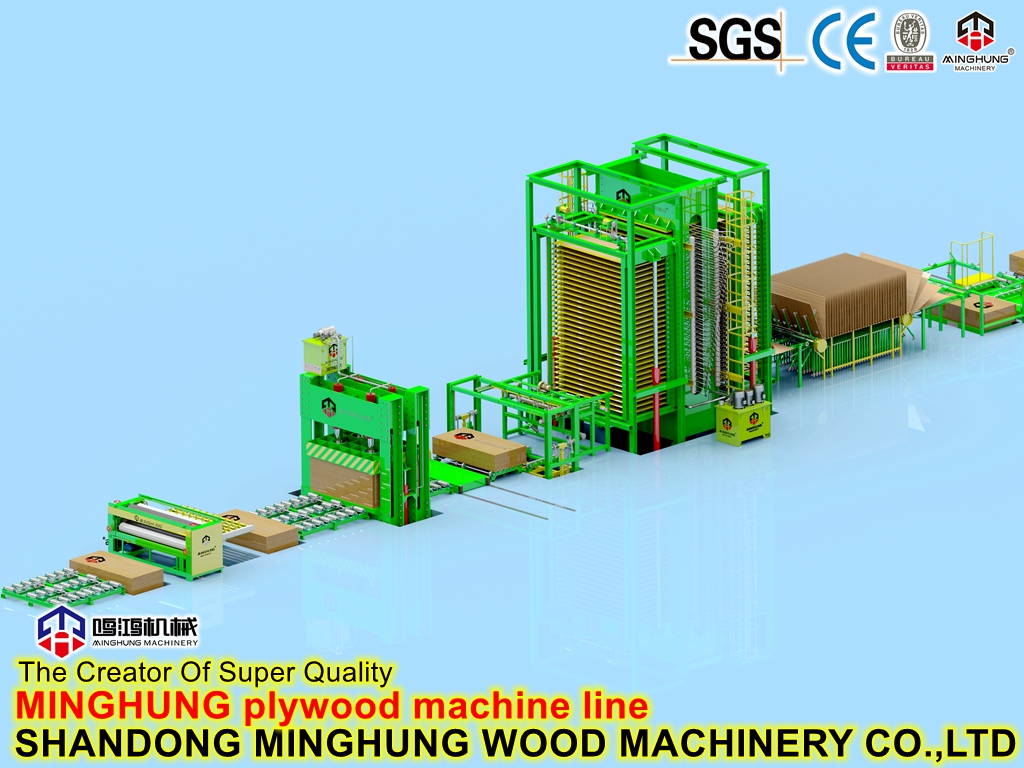

Annual 50000 M³ Medium-Thickness Plywood Production Line

Core Production Process Flow

This production line is designed to use fast-growing woods like poplar and eucalyptus as the primary raw materials to produce medium-thickness panels between 8-30mm, mainly used in concrete formwork, packaging, and furniture core boards. The entire process can be divided into five core sections: Raw Material Preparation, Veneer Drying & Processing, Glue Application & Layup, Hot Pressing, and Finishing.

Raw Material → Log Debarking → Block Peeling → Veneer Drying → Veneer Sorting → Glue Spreading → Layup → Pre-pressing → Hot Pressing → Edge Trimming → Sanding → Grading & Inspection → Packaging & Warehousing

| Section 1: Raw Material Preparation & Veneer Production |

The goal of this section is to convert raw logs into dried veneer of uniform specifications.

1. Log Bucking

Process: Cut purchased logs to the length required by the veneer lathe (typically 2600mm or multiples of 1300mm).

Equipment: Chain saws or circular saws.

Capacity Consideration: The efficiency of this process must meet the continuous feeding demand of the veneer lathes, usually requiring multiple saws.

2. Log Debarking

Process: Remove bark using a debarker. Bark contains no fibers, reduces bond strength, and wears down equipment.

Equipment: Drum or ring debarker.

Key Parameter: Debarking rate must be >95%, processing capacity must match the production line rhythm (~30-40 logs/hour).

3. Log Cooking/Steaming

Process: Soak debarked logs in hot water tanks (60-80°C) for 8-24 hours.

Purpose: Softens lignin, making the logs pliable for peeling smooth, high-quality veneer without splinters.

Capacity Consideration: The size and number of cooking pools must ensure a continuous supply of softened logs, the first critical point for ensuring capacity.

4. Veneer Peeling

Process: This is a core process. The softened log is fixed on a lathe and rotated around its central axis while a sharp blade peels it into a continuous ribbon of veneer.

Equipment: Spindle-type veneer lathe (for large-diameter logs).

Key Parameters:

Peeling Thickness: Calculated based on target finished thickness and number of piles. E.g., for an 18mm thick 11-ply board, veneer thickness is approx. 1.6mm. Thickness tolerance must be controlled within ±0.05mm.

Peeling Length: 1300mm or 2600mm.

Capacity Bottleneck: An annual output of 50,000 m³ requires 2-3 high-performance veneer lathes to meet the demand of the subsequent dryer.

| Section 2: Veneer Drying & Processing |

The goal of this section is to control veneer moisture content (MC) for effective gluing.

1. Veneer Drying

Process: The wet veneer from peeling (MC 60%-100%) is conveyed into a dryer.

Equipment: Roller dryer (preferred, better for veneer flatness) or mesh belt dryer.

Key Parameters:

Drying Temperature: 160-180°C (steam heated).

MC after Drying: 8%-12%. This is an absolutely critical index. Too high causes blisters, too low causes over-absorption of glue.

Core Capacity Bottleneck: This is the biggest bottleneck of the entire line. An annual output of 50,000 m³ requires 2 large dryer lines with 10-15 sections, operating 24/7.

2. Veneer Clipping & Grading

Process: The dried continuous veneer ribbon is clipped into sized sheets according to requirements and graded by workers or vision systems based on defects like splits, knots, and holes.

Grading Principle: High-quality defect-free veneer is used for face/back layers; veneer with minor defects is used as core layers after patching; severely defective veneer is used for filler or waste.

Capacity Consideration: The clipping and grading stations require significant manpower, and their speed must match the output speed of the dryer.

3. Veneer Patching

Process: Cracks and holes in the core veneer are filled using patching machines and putty to improve yield.

| Section 3: Glue Application & Layup |

The goal of this section is to apply adhesive to the veneer and stack it into mats.

1. Glue Application (Spreading)

Process: The graded veneer sheets are passed through a four-roll glue spreader to apply adhesive evenly on both surfaces.

Adhesive Type: Commonly Urea-Formaldehyde (UF) for interior use; or Phenol-Formaldehyde (PF) for exterior use.

Key Parameter: Spread amount must be precisely controlled (typically 120-180g/m²), determined by roller speed and gap.

2. Layup (Assembling)

Process: The glued veneer sheets are stacked manually or automatically with the grain direction "cross-oriented". The structure is: Face veneer (grain longitudinal) → Core veneer (grain transverse) → Back veneer (grain longitudinal).

Equipment: Automated layup machines are a necessary configuration for a 50,000 m³ capacity. They significantly increase efficiency (can reach 15-20 seconds/mat), reduce labor, and ensure layup accuracy (avoid gaps or overlaps).

Capacity Key: The layup speed directly determines the production line's cycle time.

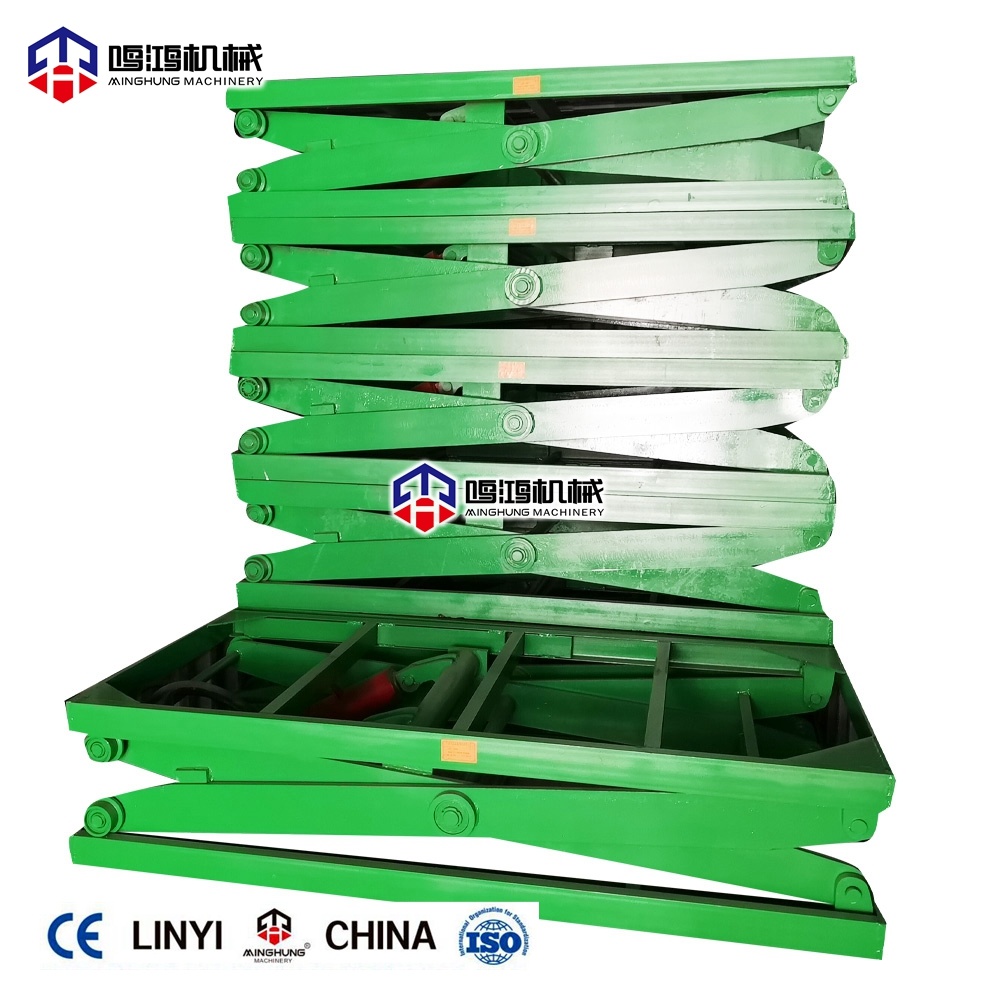

3. Pre-pressing (Cold Pressing)

Process: The assembled mats are sent to a cold press where high pressure (0.5-1.5 MPa) is applied at room temperature for a period (5-15 minutes).

Purpose: To preliminarily bond the mat into a solid unit for easier transportation and loading into the hot press, preventing mat collapse.

| Section 4: Hot Pressing |

This is the core of production, determining the final physical properties of the product.

1. Loading & Hot Pressing

Process: The pre-pressed mats are automatically loaded into each opening of a multi-opening hot press by a loader, which then closes to apply pressure and heat.

Equipment: 15-20 opening multi-opening hot press (with automatic loaders/unloaders), typically in 4'x8' (1220x2440mm) or 4'x9' (1220x2745mm) platen sizes.

Key Process Parameters (Example for 18mm PF board):

Temperature: 140-150°C

Pressure: 2.5-3.5 MPa

Time: Approx. 15-18 minutes (≈1 minute/mm)

Core Capacity Calculation: An annual output of 50,000 m³ typically requires 2 such hot presses. Calculation: A single 20-opening press produces ~2.5 m³ per press cycle. With a cycle time of ~45 minutes (including loading/unloading), single press daily output is ~70 m³. Two presses yield ~140 m³/day, reaching ~42,000 m³ annually. Accounting for efficiency loss, two presses are necessary to meet the 50,000 m³ demand.

2. Unloading & Cooling

Process: The pressed panels are removed by the unloader and immediately placed on cooling racks, spaced apart for forced cooling.

Purpose: Stops the thermal reaction, preventing deformation and embrittlement caused by residual heat.

| Section 5: Finishing & Packaging |

The goal of this section is to refine the rough panels into qualified commercial products.

1. Edge Trimming

Process: Use a double-saw cross-cut and edge trimming machine to cut away the rough edges formed after pressing, creating neat rectangular panels.

2. Sanding

Process: This is the final critical for ensuring thickness accuracy and surface quality. Panels pass through a 6-head wide-belt sander (coarse, fine, finish sanding).

Purpose: Eliminates thickness variation, pre-cured surface layers, and surface defects, achieving a smooth and flat surface.

Key Parameter: Sanding amount 0.1-0.3mm, thickness calibration accuracy ±0.1mm.

3. Grading, Inspection & Packaging

Process: 100% inspection of finished panels. Check visual defects and test properties like Modulus of Rupture/Elasticity (MOR/MOE) according to national standards (e.g., GB/T 9846), then grade accordingly (e.g., Premium, First Grade, Qualified).

Packaging: Qualified products are bundled with plastic film and strapping, labeled, and stored for sale.

Main Equipment Configuration & Selection Suggestions (50,000 m³/Year)

Key equipment must have sufficient processing capacity, precision, and reliability to ensure output and quality.

Section | Equipment Name | Recommended Specifications | Notes |

Raw Mat'l | Debarker | Dia. ≥600mm, Capacity 30-40 logs/hour | For large-diameter logs |

Peeling | Veneer Lathe | Spindle-type, Length 2600-2700mm, Dia. 200-800mm | Core equipment, high precision, thickness 1.5-3.5mm |

Drying | Veneer Dryer | 10-15 Sect. Mesh Belt or 4-Tier Roller, Temp ≥150°C | Capacity bottleneck, must ensure sufficient drying power |

Gluing | Glue Spreader | Working Width ≥1400mm | With auto glue mixing & feeding system |

Forming | Layup Line | Semi-/Fully-Automatic Layup Station | Greatly improves efficiency |

Pre-press | Pressure ≥200 Tons, Size 1400x2700mm | With auto load/unload |

Pressing | Hot Press | Multi-opening, 15-20 openings, Platen 1450x2950mm, Pressure ≥2500 Tons | Most critical equipment, auto load/unload recommended |

Finishing | Edge Trimmer | Double-saw Cross-cut & Edge Trimming |

|

Sander | 6-Head Wide Belt Calibrating Sander, Width ≥1400mm | Ensures final thickness accuracy & finish |

Auxiliary | Boiler | 10-15 T/h Biomass-Fired Steam Boiler | Provides heat for drying and pressing |

Dust Coll. | Centralized Dust Collection System | Meets environmental standards |

Air Comp. | Large Screw Air Compressor + Air Tank | Provides pneumatic power |

wood debraker

veneer peeling machine

drying mchine

plywood glue spreading

cold press machine

hot press

sawing mschine

sander

Thickness Range and Primary Applications

In the plywood industry, "medium-thickness panel" is a relative term, typically referring to panels with a thickness between 8mm and 30mm. Panels in this range combine sufficient structural strength with relatively lightweight properties, making them one of the most widely used plywood products.

Thickness Range | Primary Application Scenarios |

8mm - 12mm | Concrete Formwork: Used for less demanding slabs, wall casting, with relatively fewer reuses. |

Furniture Substrate: Used for drawer sides, cabinet backs, sofa frames, tabletops (requires surfacing). |

Packaging Cases: Manufacturing packaging cases and pallets for medium-sized equipment. |

13mm - 18mm | Concrete Formwork (Mainstream): This is the most commonly used thickness range on construction sites. It offers high strength and multiple reuses, used for casting main structures like beams, columns, and floors. |

Container Flooring: Used as wooden flooring for dry freight containers, requiring extremely high strength and wear resistance. |

Truck and Trailer Body Linings: Used for floors and sidewalls of truck bodies, offering good load-bearing properties. |

19mm - 25mm | Heavy-Duty Packaging: Used for large cases for heavy machinery and equipment, providing extremely strong protection. |

Industrial Pallets/Platforms: Used as base plates or platform boards under machinery. |

Building Construction: Used for webs of I-joists. |

Specialty Furniture: Used for tabletops, dining tables, and workbenches requiring a solid feel. |

26mm - 30mm+ | Heavy-Duty Platforms & Flooring: Used for high-capacity shelving platforms and flooring in workshops and warehouses with extreme load requirements. |

Special Structural Uses: Used for special support structures in stage building and exhibition displays. |

Cold Storage Flooring: Used as insulating underlayment for cold storage floors. |

Who We Are?

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

For more information, welcome contact us, we will reply you quickly and offer working videos with you.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com