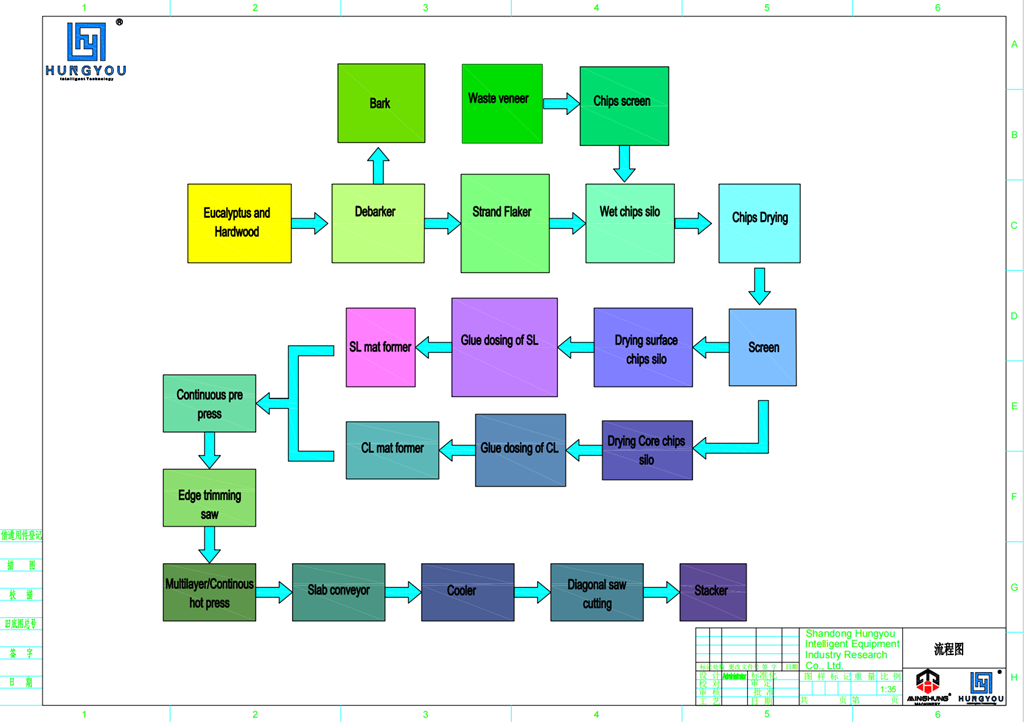

Ⅳ.Core Advantages of "40-Meter Length + 120-Second Curing"

1. Ultra-High Production Capacity: A 40-meter length combined with a 120-second curing time enables an extremely high production line speed. Curing Time (T) = Press Length (L) / Line Speed (V). Therefore, V = L / T = 40m / 120s ≈ 0.333 m/s. Assuming a finished panel width of 2.5 meters, the theoretical hourly output is: 0.333 m/s * 2.5m * 3600 s/h ≈ 3000 m²/h. Considering practical efficiency (e.g., belt changes, maintenance), the annual capacity can reach 300,000 - 500,000 m³ or even higher. This makes it ideal for large-scale OSB plants.

2. Capability for Thick Panel Production: Producing thick panels (e.g., 25mm, 30mm, or thicker) requires longer curing times to ensure full resin curing in the core. The 40-meter length provides sufficient space, allowing safe and effective production of high-quality thick panels within 120 seconds or slightly longer, without excessively sacrificing speed.

3. Optimized Curing Process: The 40-meter length allows for more process control zones. This enables engineers to design finer, more tailored process curves (temperature profile, pressure profile, closing speed profile) that closely match the resin curing reaction requirements (e.g., different needs at different stages), resulting in:

3.1 Higher Quality Panels: More uniform density distribution, better internal bond strength, lower thickness swelling, more stable dimensions.

3.2 Shorter Curing Times: Precise control (e.g., rapid heating at the inlet, high pressure promoting heat transfer) allows achieving the relatively short 120-second curing time while ensuring quality.

3.3 Adaptability to Different Raw Materials/Formulations: Greater flexibility to adjust the process for different wood species, strand moisture contents, or resin formulations.

4. Energy Saving & Reduced Consumption:

4.1 Continuous Production: Eliminates the energy consumption associated with opening/closing and loading/unloading of batch presses.

4.2 Efficient Heat Transfer: The steel belt system in continuous presses generally has higher heat transfer efficiency than the platens of multi-opening presses.

4.3 Precise Control: Zone control prevents excessive heating/pressing, reducing wasted energy.

5. High Automation & Stability: Continuous flat-press lines are highly automated, with precise and stable control of process parameters (temperature, pressure, speed), minimizing human influence and ensuring consistent product quality.

6. Reduced Unit Cost: Ultra-high capacity spreads fixed costs (equipment depreciation, energy, labor), improving economic efficiency.