What Is Veneer Dryer?

Plywood is a very strong and durable composite panels made from three or more wood veneers bonded together with an adhesive. In order to reduce the shrinkage and improve the strength of plywood, layers are glued together so that the wood grain in each veneer layer is perpendicular to the grain of the previous layer. And after producing wood veneer by veneer peeling machine, the moisture of wood veneer are very high, about 70%, 80%, so for making plywood, should first drying wood veneer, after drying, wood veneer moisture will be about 10%.

Veneer dryer machine can be divided into three types, they are veneer press dryer, veneer roller dryer, and mesh veneer dryer, they have their own characters and advantages.

Now let me simple introduce these three types of veneer dryer machine to you, then you can choose the suitable veneer dryer machine according to your own conditions and needs.

1. VENEER PRESS DRYER MACHINE, it can be divided into two kinds, one is veneer dryer machine using square tube as the hot platen, another is veneer dryer machine using hot platen same with hot press machine.

this is the first one-square tube veneer dryer machine, it can be 15layers, 20layers, the pressure is small 50t, it can be oil heating or steam heating, the drying effect is really nice and price is very favorable. One hour about 0.7cube/h

This is the second one-hot press veneer dryer machine, it use same hot plates with plywood hot press machine, the hot plates is very hard and flat, heating transfer very fast, high work efficiency.

These two veneer press dryer’s layers can be customized according to your needs, and capacity/hour less than 1m³.

2. VENEER ROLLER DRYER, inner use many many rollers, to driving and heating wood veneer.

Its length/section, floors, also can be produced according to your needs and conditions, for example, it can be 1 floor, two floors, three floors, four floors, and it can be 20m, 24m, 30m, 40m.

It can be feeding by your workers, also can be automatic infeed and outfeed.

And roller dryer is suitable for big production capacity, if you have plan to enlarge your business, this maybe a good choice for you. So tell us your production capacity one day require, we will offer you the most suitable configuration of veneer roller dryer machine.

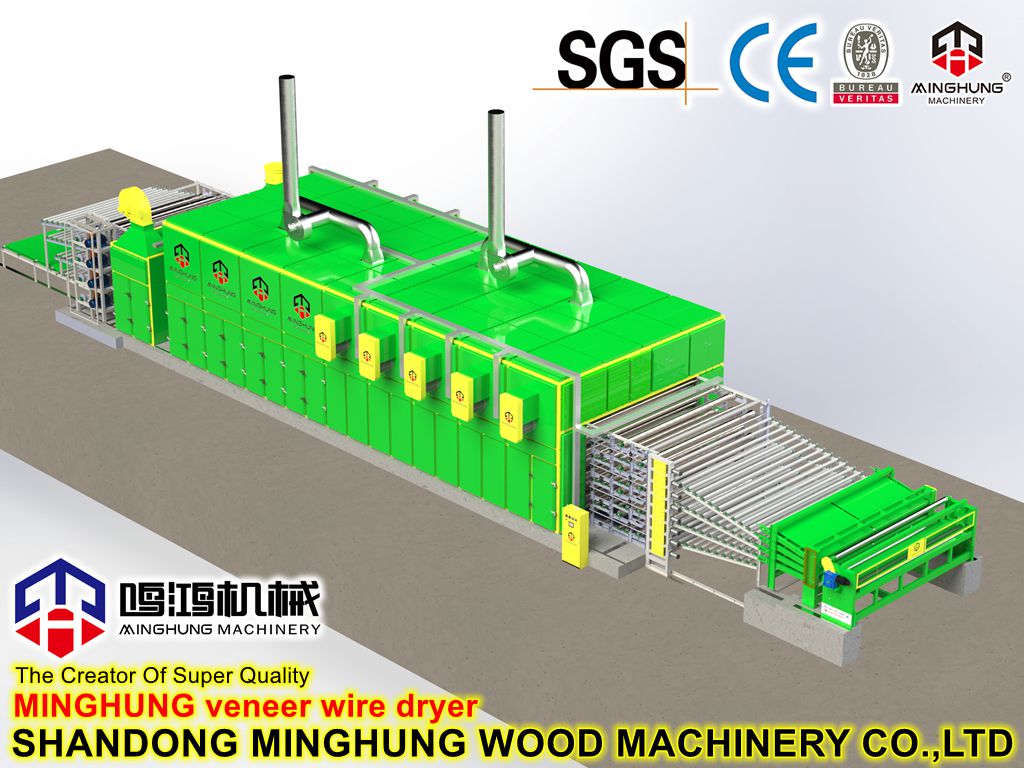

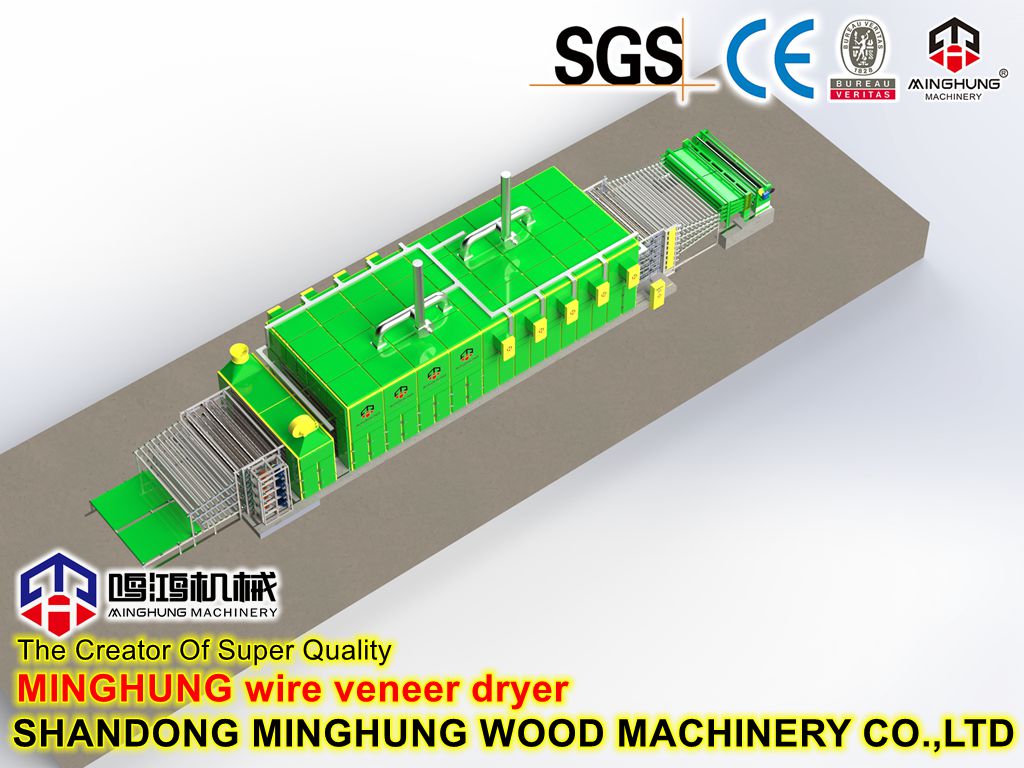

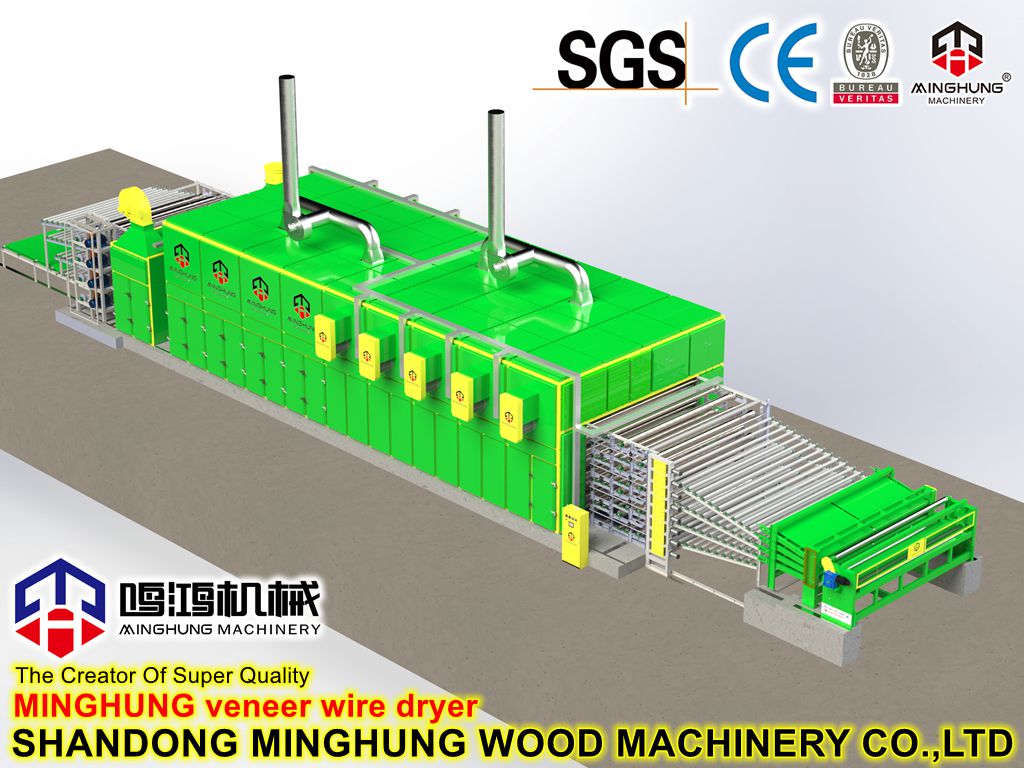

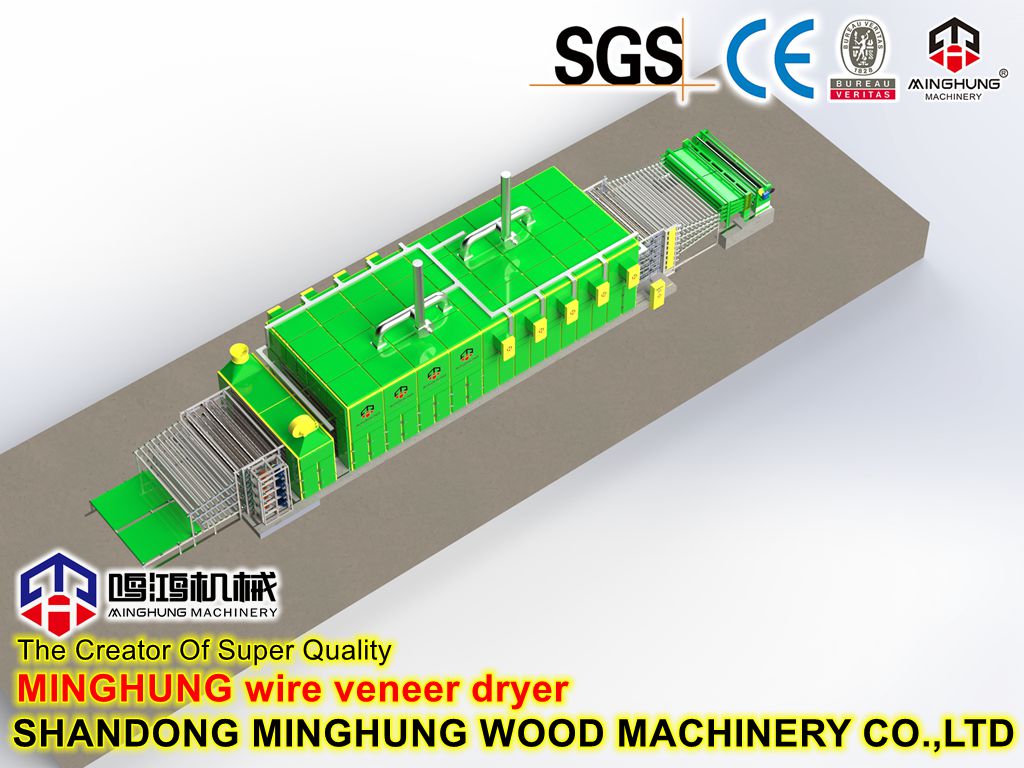

3. MESH FACE VENEER DRYER, from outside, you almost can not see the difference with roller dryer, but inner material is totally difference, this use net bag/mesh for drying wood veneer, this type can dry very thin face veneer, and also big capacity. it can be 1 floor, two floors, three floors, four floors, and it can be 20m, 24m, 30m, 40m.

It can be feeding by your workers, also can be automatic infeed and outfeed.

Veneer dryer machine can be affected by many factors, like original moisture, thickness, temperature, workers work efficiency...

Our product Roller veneer dryer for drying original wood veneer, remove abundant humidity, in the end, the wood veneer humidity will be 5%-10%, so it is suitable for making plywood.

Veneer roller dryer are suitable for big drying capacity per day, it can be different length, width and floors. For example, some our clients choose width 4500mm, length 32meters, and four floors, and this big roller dryer can drying 100m3 per day.

Our roller dryer use very thick material for frame and doors, so its weight are heavy a lot; use unique air flue and big fans to increase the production capacity; and use Siemens motor to make sure good quality and powerful energy; even the very small parts like the bearings, we insist choosing the good quality; and each kinds of parts have their own models, so before loading, we will packed each of them and make Marks, so when roller dryer reaches your factory, it is easy for you to know what are they.

Roller dryer includes many different parts, so the production technology and worker rich experience are important, and our factory with this advantage.

Choosing our roller dryer, you can use many years with good performance.

Welcome contact us for more information, we will offer the suitable dryer for you according to your own conditions and requires.

Veneer dryer

The veneer (plywood) dryer can be divided into three heating forms: hot air heating, steam heating, and heat transfer oil heating according to different heating forms. According to different fuels, it can be divided into fuel oil, gas, coal, firewood, and electricity. The equipment can be divided into manual loading and automatic loading. The veneer enters the dryer, and according to the set value, the temperature and humidity in the dryer are automatically controlled, so that the drying material can be leveled and the moisture can be controlled uniformly. The equipment can determine the size of the equipment according to the user's output, and it can be divided into automatic board and manual board. This equipment has large output, high degree of automation, low cost of use, uniform drying, and good effect. Through drying, it can avoid mildew and blue change of plates in high temperature and high humidity environment (such as eucalyptus wood, rubber wood, poplar, camphor It is ideal in the field of veneer processing, flame retardant veneer production, plywood production, flame retardant plywood production, and dyed veneer (board) production. Veneer drying equipment.

product description

Product advantages: This equipment has a high degree of automation, low operating cost, small footprint, and can be operated 24 hours a day, saving labor, and the annual labor cost saving can reach 150,000 US dollars.

Obvious features:

1. High degree of automation, automatic loading, labor saving, automatic heating, dehumidification, high drying intensity, long drying time, high moisture saturation, and energy saving.

2. Dry evenly. The peeled veneer undergoes heat exchange and moisture removal in multiple sections, and after drying for about 1.5 hours, the moisture content is low and uniform, which can meet the production needs of veneer and plywood.

3. The output is large. According to the needs of different users and different materials, the output of the equipment can reach 1---5 cubic meters/H.

4. The equipment adopts fin-type heating device, which has large heat exchange area, fast temperature increase, large circulating air volume, many cycles, high heat exchange efficiency, high exhaust water saturation, energy saving, and low use cost, which is better than roller type veneer. The drying equipment saves energy by more than 40% (the roller adopts the air spray method, the contact time between the hot air and the plate is short, and the heat exchange efficiency is low).

5. A piece of equipment investment can be used for more than ten years, super cost-effective

6. The failure rate is low, the network belt is worn, and the network is disconnected, and the failure rate of the pallet is low.

7. The equipment adopts vertical plate loading and drying. The operation time of the plate skin in the equipment is long, which can reach 1-2 hours. The temperature can be controlled according to the section. 13----15min, the folding type veneer dryer has large output, low energy consumption and low drying cost.

#veneerdryer #veneerdryermachine #plywoodveneerdryer

Whatsapp: +8618769900191 +8615805493072 +8615589105786

Email: www.plywoodmachineline.com