Principle of Veneer Rotary Cutting ?Veneer Peeling

Veneer peeling is mainly used to produce veneer, which is a thin sheet of wood with a uniform thickness and is the main raw material for plywood. Rotary cutting is mainly used to produce thin or medium thickness veneers. high productivity

Veneer Rotary Curve (Rotary Kinematics)

During wood peeling, the main motion is the rotary motion of the wood segment, and the feed motion is the constant velocity linear motion of the rotary knife.

In order to obtain a continuous strip of equal-thickness veneer, it is required that the rotary motion of the wood segment and the linear motion of the rotary knife must maintain a strict kinematic relationship during rotary cutting to ensure that the thickness of the veneer is equal to the feed per revolution.

veneer peeling curve

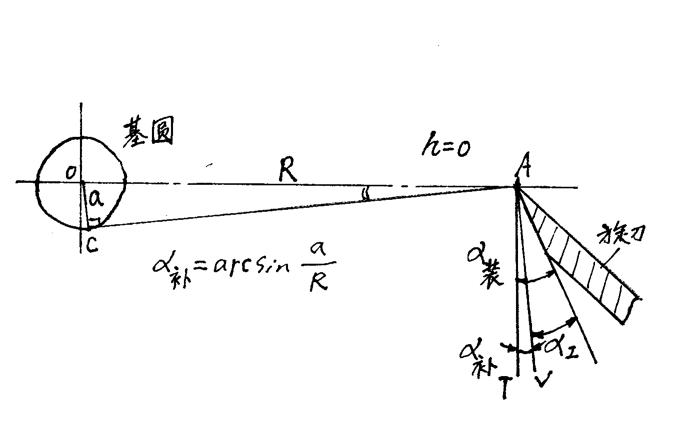

Polar coordinate equation: (tool moves from point A to point A')

Ф=ωt

(ω- angular velocity of wood segment rotation ω = 2πn/60 ; n- angular velocity of wood segment return r/min; t- time )

Horizontal direction: x=Vf*t (Vf——feed speed of rotary knife mm/s

Vf=S×n/60 S——the thickness of the veneer mm)

X=Vf*t=S*n/60*Ф/ω=S*n/60*Ф/2πn/60

=S/2π*Ф

=a*Ф

From the triangle we get:

R2=a2Ф2+h2

where:

R——Instantaneous radius of wood segment (mm)

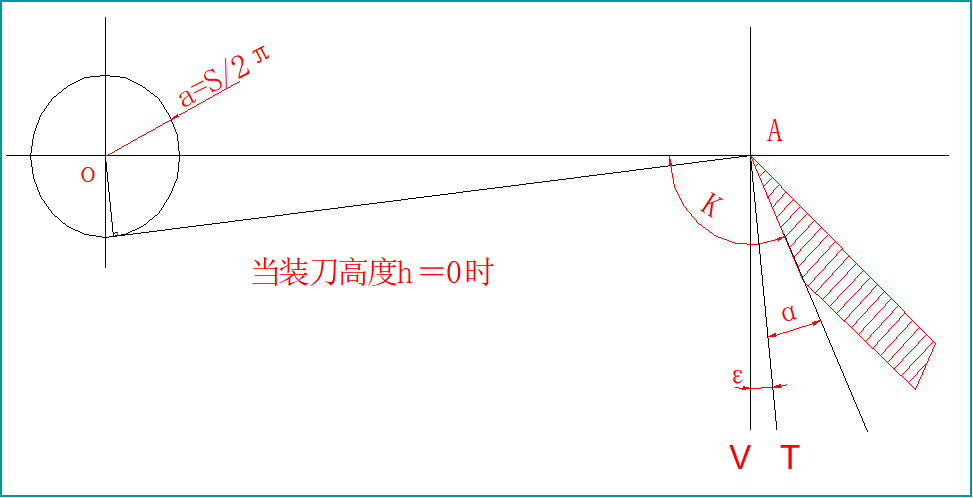

a——Polar normal distance or base circle radius of involute (mm) a=S/2π

Ф——polar angle, which is the counterclockwise angle from the ox direction.

h——The height of the knife (mm)

R2=a2Ф2+h2

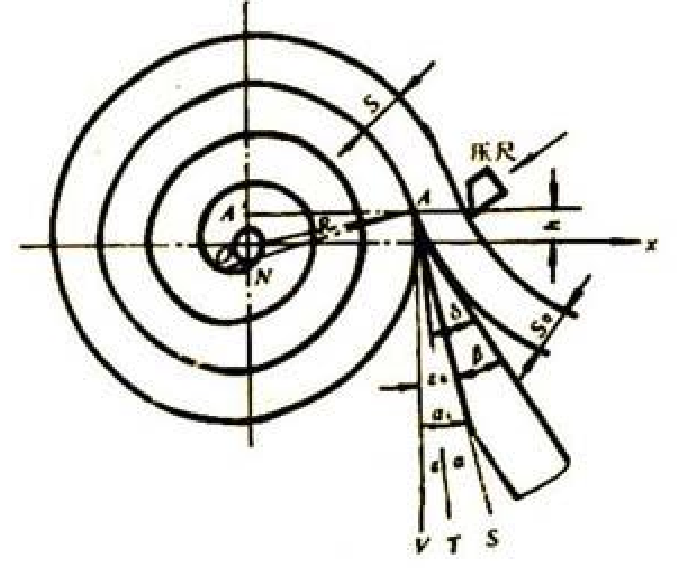

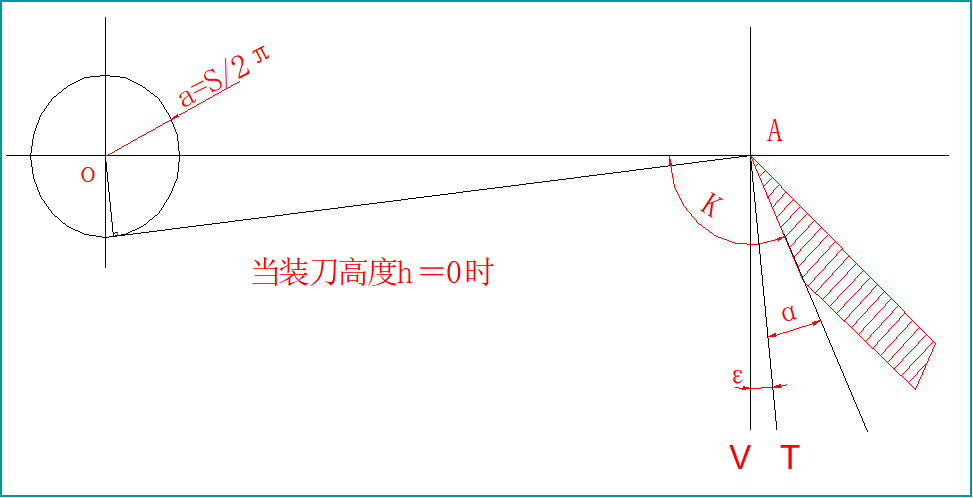

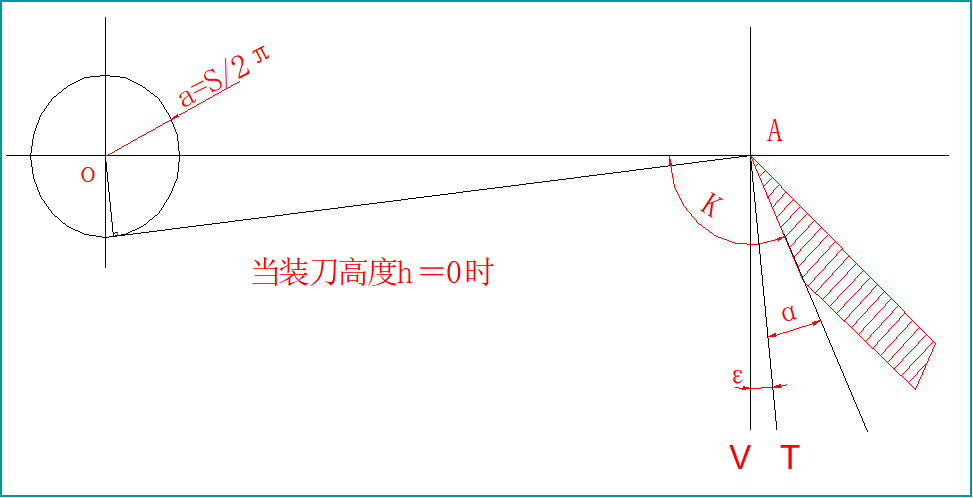

When the installation height h=0:

R2=a2Ф2 That is: R=aФ

The tangent curve is an Archimedes spiral

When the height of the tool is h<0 or h>0: the rotary cutting curve is the generalized involute of the circle.

When the height of the knife is h=∓a: the rotary cutting curve is the involute of the circle.

Explanation: when h=0, R=aФ,

∆R=S=a(Ф2-Ф1)

=a 2π (constant)

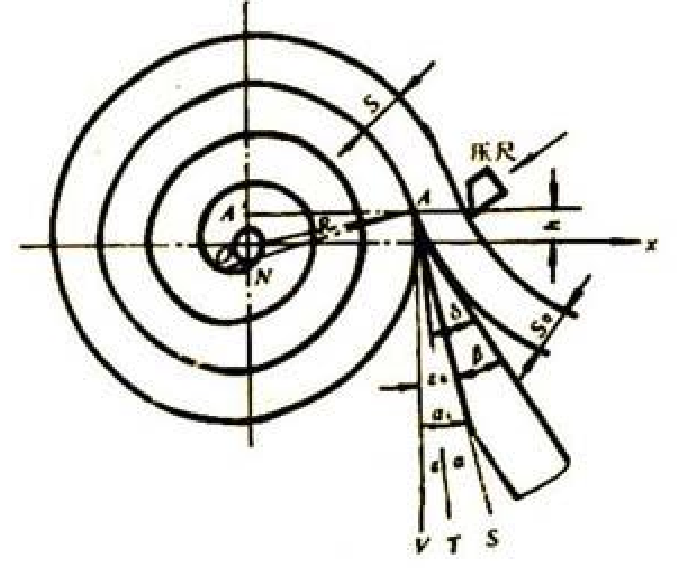

The main angle parameters and their changes in the process of veneer peeling:

The main angle parameters in the peeling process:

(1) Wedge angle β

The wedge angle is commonly known as the grinding angle, which is the angle between the front and the back of the rotary knife, represented by β.

The size of the wedge angle is mainly determined according to parameters such as the material of the rotary knife, the thickness of the veneer, the tree species, the moisture content and its temperature.

In the production of plywood, in order to rotary cut high-quality veneer, on the premise of ensuring the sufficient strength of the rotary knife, the value of the β angle should be reduced as much as possible, usually β=18°~23°. When other conditions are the same, when peeling hard wood and thick veneer, the β value should take the larger value.

Rotary knife beta value of commonly used tree species in domestic rotary cutting:

Species Pine Basswood Ash Poplar Birch

β value (°) 18~21 18~19 20~22 17~18 19~20

(2) Cutting angle δ

The cutting angle is the angle between the tangent line AT of the surface of the wood segment that is in contact with the cutting edge of the rotary knife and the front face of the rotary knife, expressed as δ.

The cutting angle has a great influence on the processing quality. After the veneer is peeled, it changes from a curved shape to a straight plate shape, and it is bent in a reverse direction. The larger the cutting angle, the greater the degree of bending, and cracks appear on the back of the veneer. The more likely it is, therefore, reducing the cutting angle can reduce the occurrence of backside cracks.

In the process of rotary cutting, the diameter of the wood section gradually decreases, and the curvature of the veneer at the moment of cutting becomes larger and larger, that is, the possibility of cracks in the veneer is correspondingly increased. Therefore, the cutting angle should vary with the diameter of the wood section. decrease and decrease.

∠δ=∠β+∠а, since the wedge angle β of the rotary knife is a certain value after grinding, and it is small, if it is reduced again, the strength of the cutting edge will be significantly reduced. Reducing the cutting angle can only be achieved by reducing the clearance angle.

(3) Rotary cutting machine knife with high knife angle

In order to ensure the quality of peeling, the size of the back angle should be appropriate. When the relief angle is too large, if the wedge angle remains unchanged, the cutting angle is also large, and the possibility of cracking and cracking of the veneer is high; at the same time, the vibration of the tool holder is caused due to the reduction of the contact area between the flank surface and the wood section. , the blade is easy to cut into the wood below the separation line, resulting in uneven thickness of the veneer (such as wavy changes), so it is better to have a smaller back angle. Since the contact area is related to the diameter of the wood segment, the smaller the diameter of the wood segment, the smaller the contact area. Therefore, in order to ensure the necessary contact area, the rear angle should be reduced with the reduction of the diameter of the wood segment.

The small rear angle can reduce the possibility of cracks in the veneer, but if it is too small, the contact area between the rotary cutter and the wood section will be too large, and the pressure on the wood section will increase, which will not only cause excessive Large friction loss, and the wood section is bent, the smaller the diameter of the wood section, the more serious the bending, which will also cause uneven thickness of the veneer, and even cause local splitting of the wood section (the veneer may become a corrugated board)

(3)The relationship between the diameter of the wood segment and the rear angle:

In the process of veneer peeling, in order to ensure the quality of peeling, the size of the relief angle should be appropriate; in order to ensure normal peeling conditions, it is also required that the relief angle must be reduced with the reduction of the diameter of the wood segment.

Wood segment diameter (mm) 260-300 320-420 400-600 620-800

Relief angle (°) 0.5-1 1-2 2-3 3-4

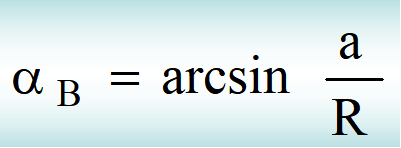

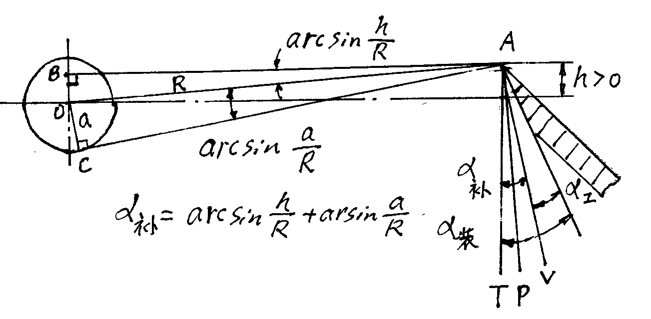

(4) Supplementary angle ε and rotary cut angle K

The supplementary angle ε is the angle between the tangent line AT and the vertical line AV, denoted by ε.

The rotary cutting angle is the angle between the horizontal plane passing the center of the card shaft and the back of the rotary knife, expressed by K

The natural change of the rotary knife angle in the process of veneer rotary cutting

Since the rotary cutting curve is not an arc curve, the working clearance angle of the rotary knife (ie, the moving clearance angle) is not equal to the rest angle of the rotary knife, that is, the clearance angle of the installation tool. In the process of rotary cutting, with the reduction of the diameter of the wood segment, whether and how the working angle of the rotary knife changes depends mainly on the height of the knife and the type of the knife holder.

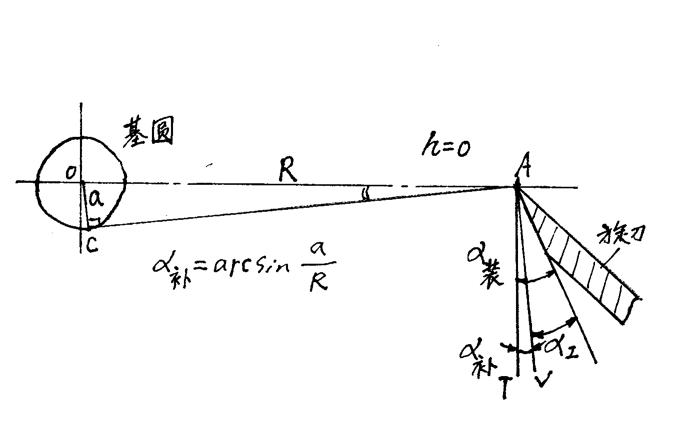

1. When the height of the knife is h=0:

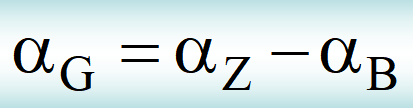

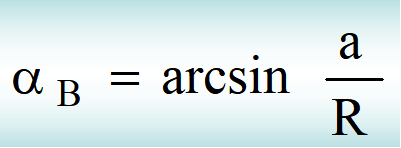

In the formula: αG—working clearance angle; αz—tool clearance angle: αB—supplementary angle.

In the formula: αG—working clearance angle; αz—tool clearance angle: αB—supplementary angle.

Natural variation of blade angle during veneer peeling

The relationship between the working clearance angle and the supplementary angle of the rotary knife when the knife installation height h=0

veneer peeling lathe , the relationship of the rotary cutter to supplement the angle

It can be seen from this formula that as the diameter R of the wood segment decreases, the supplementary angle αB increases, and the working rear angle αG decreases. This is also required in terms of technology. Even so, in this case, there are limited changes to the working rear angle, such as:

When R=300mm, s=1.5mm, αZ=5°,

a=s/2π=1.5/2π=0.2387,

αG=5°-arcsin(0.2387/300)=4.955°

And when R=60mm,

αG=5°-arcsin(0.2387/60)=4.487°

The reduction in working relief angle is only 10%.

The relationship between the working clearance angle of the rotary knife and the supplementary angle when the rotary knife height is 〉0

When the other conditions are the same, the installation height h0, the supplementary angle consists of two parts. The working clearance angle of the rotary knife can be expressed as the following formula:

When the other conditions are the same, the installation height h0, the supplementary angle consists of two parts. The working clearance angle of the rotary knife can be expressed as the following formula:

αG=αz-αB=αZ-(arcsin a/R+arcsin h/R)

Set h=1.5mm,

Then αG is from 4.669° when R=300mm to αG=1.679° when R=60mm, a decrease of 64%.

Measurement of veneer lathe knife height:

Our product 4feet Veneer production line includes 4feet log debarker, 4feet wood peeling machine, log conveyor, and 4feet vacuum veneer stacker.

The function of veneer peeling line for processing wood and produce wood veneer, as you know, wood veneer is material for making plywood, wooden furniture and others. So its quality are very important. This requires the veneer machine are good quality and strong enough.

This 4feet veneer production line, automatic veneering line, clipping of veneer, peeler bauk, can process max log length 1400mm, and max log diameter 550mm, and thickness can be 0.5-4mm.

With advanced and mature production technology, and experienced workers and professional technicians, So our veneer machine structure and characters are good. And we use good and thick materials, super machine accessories, good electric box and upgraded electric parts, So our log peeling machine are strong enough to peel kinds of hardwood like beech, birch and others, and can help you produce very accurate wood veneer with smooth surface, which will help you create much value.

Welcome contact us for more information of veneer machine, we will offer machine working video and details for you.

About veneer peeling machine veneer lathe veneer peeling lathe contact us:

whatsapp: +8618769900191 +8615589105786 +8615805493072

email: minghungmachinery@gmail.com

In the formula: αG—working clearance angle; αz—tool clearance angle: αB—supplementary angle.

In the formula: αG—working clearance angle; αz—tool clearance angle: αB—supplementary angle.