Siemens PLC Control System

Concept: The industrial automation system based on Siemens programmable logic controllers (such as S7-1500 series) is responsible for coordinating the precise control of equipment such as presses, conveyors, and temperatures.

Siemens' flagship PLC (simple logic controller) is designed for mid-to-high-end industrial automation scenarios. It has high performance, high automation and automation as its core advantages, and is suitable for complex applications such as intelligent manufacturing, process control, and motion control.

Among them, SIMATIC S7-1500 represents the current technical benchmark in the field of industrial control. Its open architecture and digital genes provide core support for the upgrade of Industry 4.0. For modern factories that pursue efficiency, reliability and intelligence, it is an ideal automation center solution.

Key Parameters

PU processing speed: < 1ms per thousand instructions

I/O points: Can be expanded to several thousand points

Memory capacity: 1MB - 20MB

Communication protocols: Profinet, Ethernet/IP

Workflow:

1. Signal acquisition: Real-time data such as temperature, pressure, and speed are obtained through sensors;

2. Logical operation: The CPU executes pre-set programs (such as PID control, interlock logic);

3. Output control: Controls the actuators like hydraulic valves, motors, and heaters;

4. Loop scanning: Repeats the above process at a millisecond level cycle.

Key Components: CPU, I/O modules, Communication modules.

Role: Automates processes and maintains parameter accuracy.

10.1-inch Touch Screen HMI

Concept: The human-machine interaction interface (HMI), as the operation terminal of the PLC system, displays the equipment status in a graphical manner and receives operation instructions.

Key Parameters

Screen size: 10.1-inch diagonal

Resolution: 1280×800 pixels

Touch type: Capacitive/Resistance

Protection level: IP65 (dust and water resistance)

Parameters:

1. Information display: Data is read from the PLC, and real-time display of temperature curves, pressure values, fault alarms, etc. is provided;

2. Instruction input: Operators can input instructions (such as start/stop, parameter adjustment) through touch screen;

3. Data interaction: Bidirectional communication with the PLC is achieved via industrial Ethernet (such as Profinet).

Key Components: LCD panel, Touch sensor, Embedded processo,Communication Interfaces.

Role: Provide intuitive operation and monitoring windows, simplify equipment management, accelerate fault diagnosis, and enhance operational efficiency.

1. The touch screen receives the operator's instructions (such as setting the temperature at 200°C)

2. The PLC interprets the instructions and controls the heating oil system to increase the temperature

3. The compressor adjusts the pressure and speed according to the PLC instructions

4. Real-time data (such as the actual temperature of 198°C) is fed back to the touch screen for display

5. The PLC automatically fine-tunes the parameters to ensure process stability.

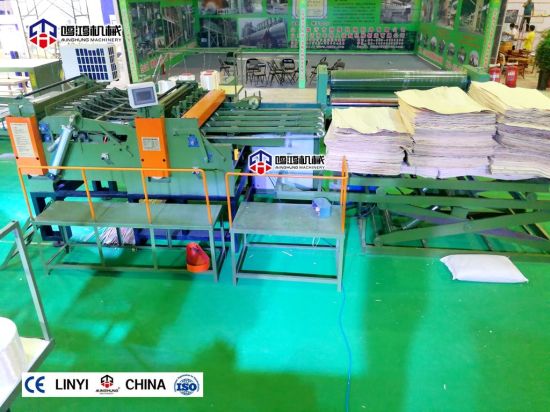

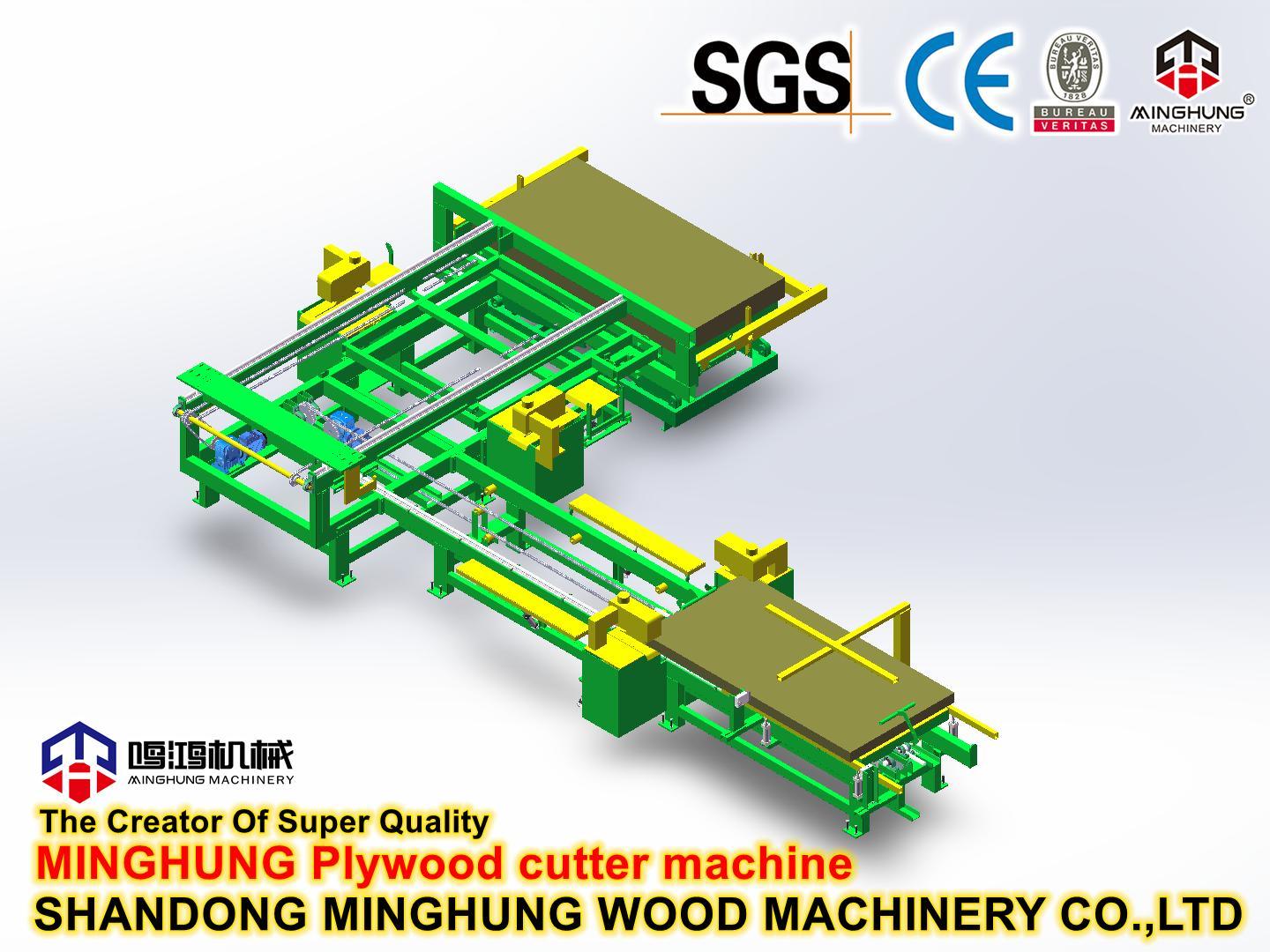

Shandong MingHung OSB&MDF Machinery Equipment is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.

Contact us for a free quote today!

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com