Large-Scale Plywood Production Drying Line

|

Product Description

The Large-Scale Plywood Production Drying Line is a high-end, continuous-operation system that integrates machinery, thermal engineering, automated control, and intelligent logistics technologies. Transcending the concept of a single machine, it provides a full-process, automated solution for modern large-scale plywood plants, from wet veneer feeding to dry veneer stacking. This production line is designed to achieve maximum productivity, consistent quality, and the lowest unit cost, serving as the core equipment for plywood enterprises to achieve large-scale, intelligent manufacturing.

|

Cpre Advantages

1. Ultra-High Production Efficiency: Featuring a continuous through-feed design, it operates 24/7 without interruption, with an annual processing capacity ranging from tens of thousands to hundreds of thousands of cubic meters of veneer, perfectly meeting the output demands of large factories.

2. Exceptional Drying Quality: Precise zone-specific temperature and humidity control, combined with uniform airflow distribution, ensure consistent moisture content for every single veneer, effectively eliminating defects like warping and cracking, thereby laying the foundation for producing high-grade plywood.

3. Significant Energy Savings: The system incorporates high-efficiency heat recovery units that reclaim waste heat from the exhaust air to preheat fresh air, drastically reducing energy consumption. Excellent insulation properties further minimize heat loss.

4. High Automation and Intelligence: The entire line is intelligently managed by a central control system, enabling unmanned operation from automatic loading, optimized drying process, speed synchronization, to automatic unloading and stacking, significantly reducing labor intensity and workforce costs.

5. Stable and Reliable Operation: Built with key components from internationally renowned brands and a robust structure designed for harsh industrial environments, it ensures trouble-free continuous operation year-round with low maintenance costs.

|

System Composition and Workflow

A complete large-scale drying line typically consists of the following seamlessly connected subsystems:

1. Automatic Feeding System:

Composition: Includes lifting tables, de-stacking devices, veneer separators, and conveyors.

Function: Automatically receives wet veneer packs delivered by forklifts and feeds them sheet by sheet, neatly, into the entrance of the drying line.

2. Continuous Drying Main Unit:

Composition: Long insulated chamber, multi-layer (or multi-mesh belt) conveyor system, zoned heating system, forced air circulation fan system, intelligent humidity exhaust system.

Function: This is the core of the production line. Wet veneers slowly pass through the dozens-of-meters-long drying chamber on conveyor belts. The chamber is divided into multiple zones with independently controlled temperature and humidity (e.g., preheating zone, constant rate drying zone, falling rate drying zone), allowing the veneers to undergo a scientifically optimized drying curve for efficient, high-quality results.

3. Intermediate Transfer and Monitoring System:

Composition: Transition conveyors, online moisture content detectors.

Function: Ensures smooth transition of veneers between different sections. The online moisture detector monitors drying effectiveness in real-time and feeds data back to the control system for real-time process parameter adjustments.

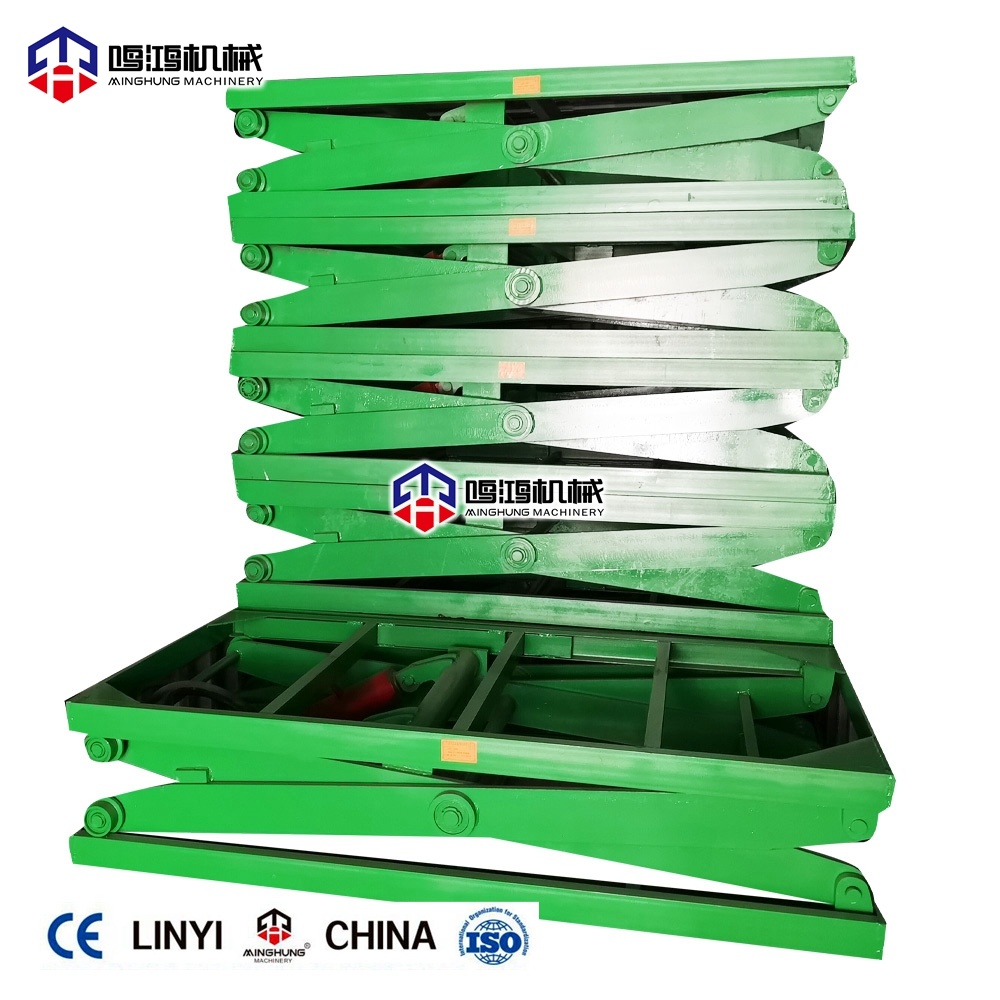

4. Automatic Unloading and Stacking System:

Composition: Unloading conveyors, cooling section, sorting device (optional), automatic stacking robots or stackers.

Function: Automatically stacks the dried veneers into neat packs, which are then transported by a packing station or AGVs to the next production stage, enabling seamless integration with downstream processes.

5. Intelligent Central Control System:

Composition: Industrial PC (IPC), Programmable Logic Controller (PLC), Human-Machine Interface (HMI), sensor network.

Function: Acting as the brain of the production line, it monitors and coordinates all subsystems, stores drying recipes for various wood species, records production data, and enables remote monitoring and fault diagnosis.

|

Applications

This production line is specifically designed for large-scale manufacturers of plywood, blockboard, container flooring, etc. It is suitable for drying large volumes of veneers from various wood species such as poplar, eucalyptus, pine, and birch, making it the cornerstone for building modern wood processing plants.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

|

Package and transport

|

What are your services?

Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

Request a Quote Today! OEM/ODM solutions available – Start your plywood business with competitive edge!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com