Plywood

1. What is Plywood?

Plywood is a type of engineered wood panel made by gluing together multiple thin layers of wood veneer. The grain direction of each layer is oriented perpendicular to the adjacent ones. This cross-graining structure makes it strong and stable.

2. Key Advantages

High Strength & Dimensional Stability: The cross-grained structure distributes strength evenly across the panel and minimizes shrinkage, swelling, or warping compared to solid wood.

Large Sheet Sizes: Can be manufactured in large formats (e.g., 4' x 8'), which is difficult with solid wood.

High Efficiency: Made from fast-growing trees, small-diameter logs, or wood waste, improving wood utilization.

Adjustable Properties: By using different wood species, adhesives, and processes, plywood can be made for various applications (indoor, outdoor, structural).

3. Main Types

By Water Resistance:

MR (Moisture Resistant): Uses urea-formaldehyde glue. Resistant to short-term cold moisture. For interior furniture and decoration. (Most common type)

WBP (Weather and Boil Proof): Uses phenolic resin glue. Highly resistant to water, weather, and even boiling. For outdoor construction and concrete formwork. (Most common exterior type)

By Surface Material:

Poplar Core: Soft, lightweight, and economical.

Eucalyptus Core: Dense, hard, and strong.

All Pine/Hardwood: Balanced performance.

Film-Faced: Coated with plastic film for easy demolding from concrete.

Overlaid/Decorative: Surfaced with valuable wood veneers (e.g., Walnut, Oak) or melamine-impregnated paper for ready-to-use furniture.

4. Primary Uses

Construction & Decoration: Walls, ceilings, subflooring, concrete formwork.

Furniture Manufacturing: Cabinets, wardrobes, tables, sofa frames, bed bases.

Packaging: Crates, pallets.

Others: Boat interiors, vehicle interiors, musical instrument speakers.

5. Common Specifications

Size: Standard size is 1220mm x 2440mm (4ft x 8ft).

Thickness: Common thicknesses range from 3mm, 5mm, 9mm, 12mm, 15mm, 18mm to 25mm.

Piles: Usually has an odd number of layers (3-ply, 5-ply, 7-ply, 9-ply) for balanced construction.

The High-Temperature Rapid Plywood Dryer, professionally used mainly for drying veneers that constitute plywood, operates on the principle of high-temperature convective heating and rapid moisture extraction.

Wet veneers are fed into the dryer by an automatic loading system and transported continuously through various zones via conveyor rollers or mesh belts. Inside the dryer, high-temperature medium (clean hot air or superheated steam) generated by the heating system is forcibly circulated by high-power, heat-resistant fans at very high velocity, perpendicularly through the gaps between the veneer sheets. The high-temperature environment causes the moisture inside the veneers to vaporize rapidly. Simultaneously, an intelligent control system precisely adjusts the opening of exhaust dampers to promptly expel the high-humidity waste gas. In energy-efficient models, a heat exchanger recovers thermal energy from this exhaust gas to preheat fresh incoming air, significantly reducing energy consumption. The entire drying process is completed within a sealed, insulated kiln, with veneers entering wet and exiting dry, forming a highly efficient continuous operation.

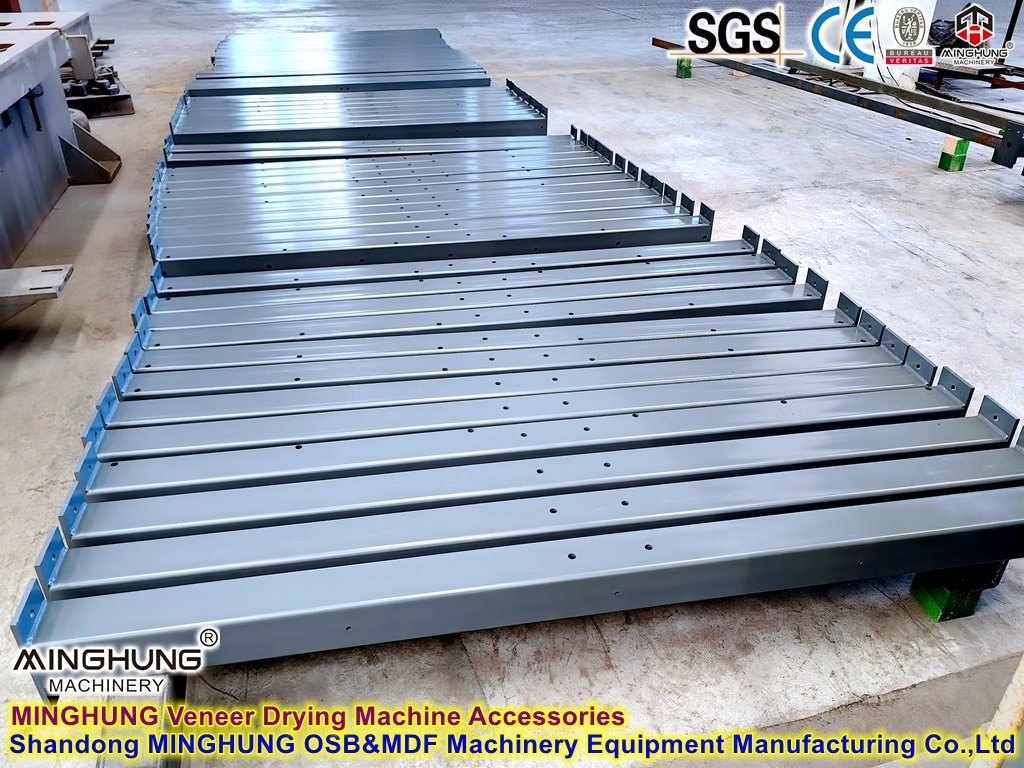

1. Kiln Body System: Constructed from high-quality galvanized or color steel plates, filled with high-density, heat-resistant insulation material (e.g., rock wool or aluminum silicate wool), typically over 150-200mm thick. This ensures a stable internal high-temperature environment and minimizes heat loss.

2. Heating System: The core is a high-temperature hot air furnace or large heat exchanger. Options based on energy availability:

Gas/Oil Hot Air Furnace: Heats air directly, temperatures can exceed 250°C.

Steam/Thermal Oil Heat Exchanger: Uses steam or thermal oil from a boiler to indirectly heat air via finned tube exchangers. Temperature depends on the source.

Electric Heating: Heats air via electric heating elements, allowing precise temperature control but with higher operating costs.

3. Circulation System: Consists of multiple high-power, high-static pressure, heat-resistant specialty fans (often centrifugal or axial) and carefully designed air deflectors and nozzles. This system creates uniform, high-velocity jets that penetrate the entire veneer stack, which is crucial for rapid and uniform drying.

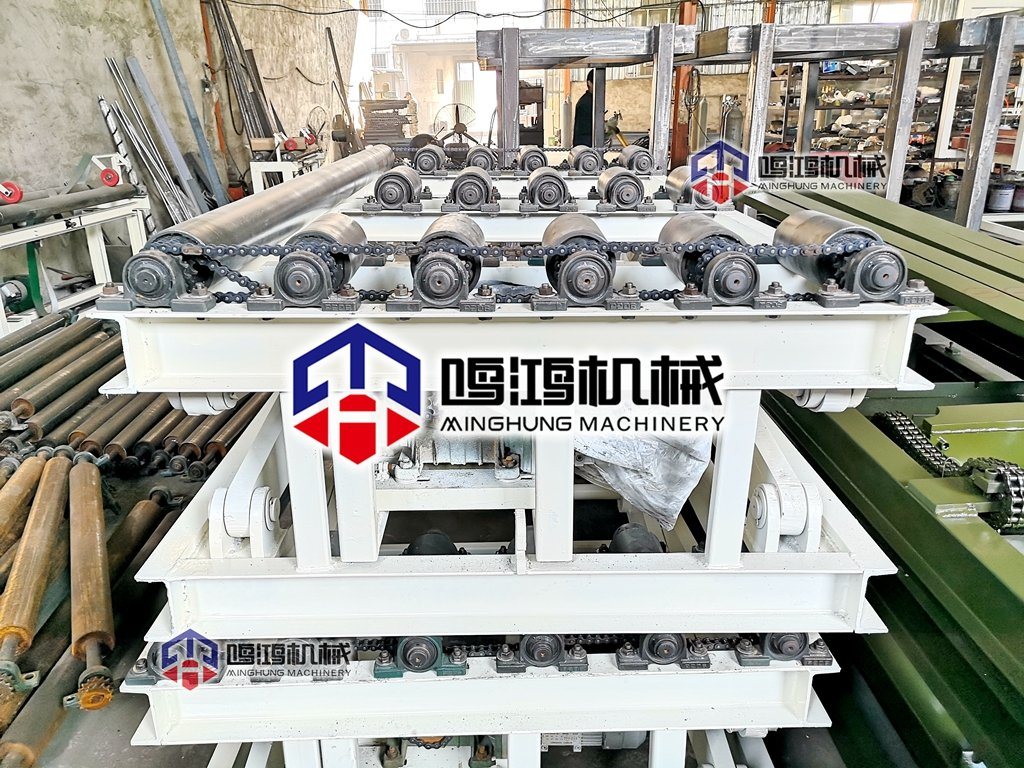

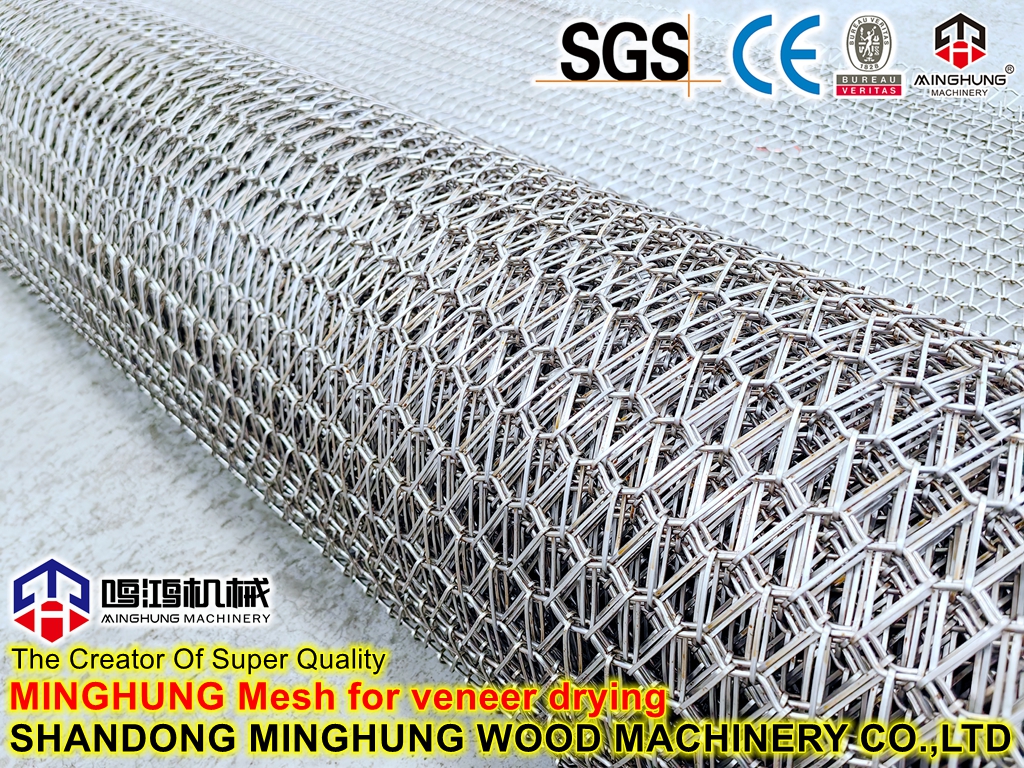

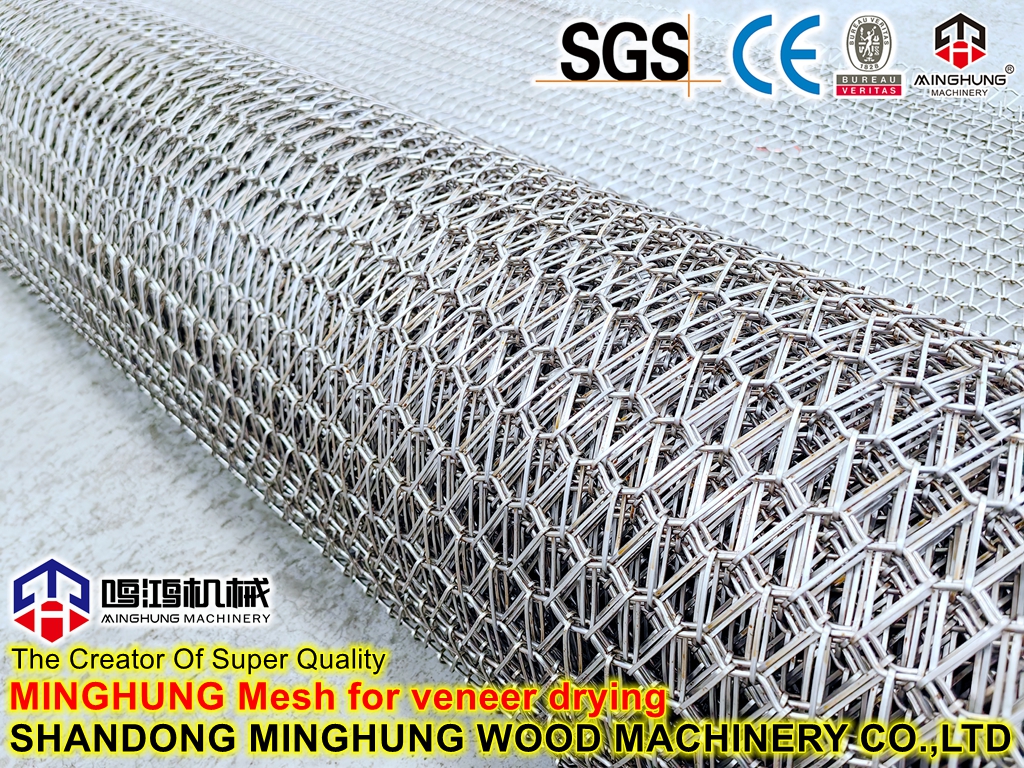

4. Conveyor System: Comprises rollers or mesh belts made of heat-resistant metal, driven by variable frequency motors via chains or gears. The speed is infinitely variable, allowing precise control of the veneer's residence time (i.e., drying cycle) inside the dryer.

5. Ventilation/Exhaust System: Includes exhaust vents, regulating valves, and exhaust fans. It removes moisture-saturated air from the kiln, maintaining a low relative humidity inside and creating the driving force for moisture evaporation.

6. Heat Recovery System (Optional but Efficient): Employs air-to-air heat pipe exchangers or plate heat exchangers to transfer thermal energy from the outgoing hot exhaust gas to the incoming fresh cold air. This can recover 20%-30% of thermal energy, markedly reducing fuel consumption.

7. Intelligent Control System: The brain of the operation. Uses a PLC (Programmable Logic Controller) and a color Touch Screen HMI (Human-Machine Interface). Features include:

Multi-Zone Control: Divides the long kiln into multiple zones (e.g., pre-heating, drying, cooling/conditioning) with independent temperature and humidity control.

Process Curve Storage: Stores pre-set drying schedules (curves) for various wood species (poplar, pine, eucalyptus, etc.) and thicknesses, accessible with one click.

Real-Time Monitoring & Logging: Continuously monitors and logs parameters like temperature, humidity, air velocity, pressure, and conveyor speed in each zone.

Fault Diagnosis & Alarm: Automatically diagnoses equipment abnormalities and triggers alarms, ensuring operational safety.

III. Key Technical Parameters

Parameter Category | Detailed Description |

Applicable Product | Plywood Veneer, Thin Wood Veneer |

Max. Operating Temperature | 200°C - 250°C (Far higher than traditional dryers at 80-120°C) |

Drying Cycle Time | 3 - 15 minutes (Varies by species, initial MC%, thickness) |

Production Capacity | Up to 50 - 300 m³ per shift (8 hours) or higher, depending on equipment size and speed |

Input Moisture Content | 40% - 60% (or even higher, e.g., Poplar) |

Output Moisture Content | Can be stably controlled at 8% - 12% (±1-2%) |

Heat Source Options | Natural Gas, Diesel, Steam, Thermal Oil, Electricity |

Conveyor Speed | Variable Frequency Drive control, typically 1 - 10 m/min (Adjustable) |

Control Method | PLC + Touch Screen, Fully Automatic Control |

Energy Saving Rate | Up to 20% - 35% energy saving compared to traditional dryers when equipped with heat recovery |

Principle: According to drying kinetics, the rate of moisture evaporation increases exponentially with rising temperature. Elevating the operating temperature from the conventional ~100°C to over 200°C drastically enhances the rate of heat transfer to the veneer and the kinetic energy of water molecules, enabling extremely rapid migration and evaporation of internal moisture.

Advantages:

1. Leap in Drying Speed: The fundamental reason for achieving "Rapid" drying.

2. Sterilization & Pest Elimination: Effectively kills insect eggs and fungi that may be present in the veneer, improving the biological durability of the final product.

3. Reduced Discoloration: The very short drying time minimizes chemical discoloration (e.g., oxidation of phenolic compounds) that can occur with prolonged exposure at medium temperatures.

Challenges & Solutions: High temperatures can exacerbate veneer cracking and warping. Therefore, it is imperative to have an extremely precise temperature and humidity control system and uniform, high-velocity airflow to ensure even heating and avoid localized over-drying or stress concentration

Implementation: "Rapid" is the result of the combined effects of High-Temperature technology, a High-Efficiency Circulation System, and Continuous Operation.

1. High Temperature: Provides the powerful driving force for moisture evaporation.

2. High-Velocity Air Penetration: The powerful fan system breaks down the saturated vapor boundary layer on the veneer surface, ensuring evaporated moisture is immediately carried away, maintaining maximum evaporation efficiency.

3. Continuous Production: Continuous feeding and discharging of veneers eliminate the time wasted on loading/unloading inherent in batch dryers, maximizing equipment utilization.

Advantages:

1. Super High Production Efficiency: Significantly increases output per unit time, meeting the demands of large-scale industrial production.

2. Reduced Floor Space: For the same output, a continuous rapid dryer can be much shorter than traditional equipment.

3. Lower Working Capital Requirements: Shortened production cycles accelerate the process from raw material to finished product, improving capital turnover.

A:Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

Q:How is your quality?

A:As an experienced manufacturer, the quality of our machines can be guaranteed and we have supplied our products to thousands of customers all over the world.

Q:How do we import from you?

A:We have the ability to provide you with a one-stop solution. You can contact us, and then we will provide you with satisfactory cooperation.

Q:Why choose you?

A:1.100% customer-oriented solutions.

2.Team members with 40+ years of experience in the wood industry.

3.The strongest awareness of protecting customer business privacy.

4.Deep insight and understanding of market mysteries.

5.Familiar with international terminology.

6.Attention to details and integrity make us grow.

If interested please contact us for a quote.