01 PRODUCTION DESCRIPTION

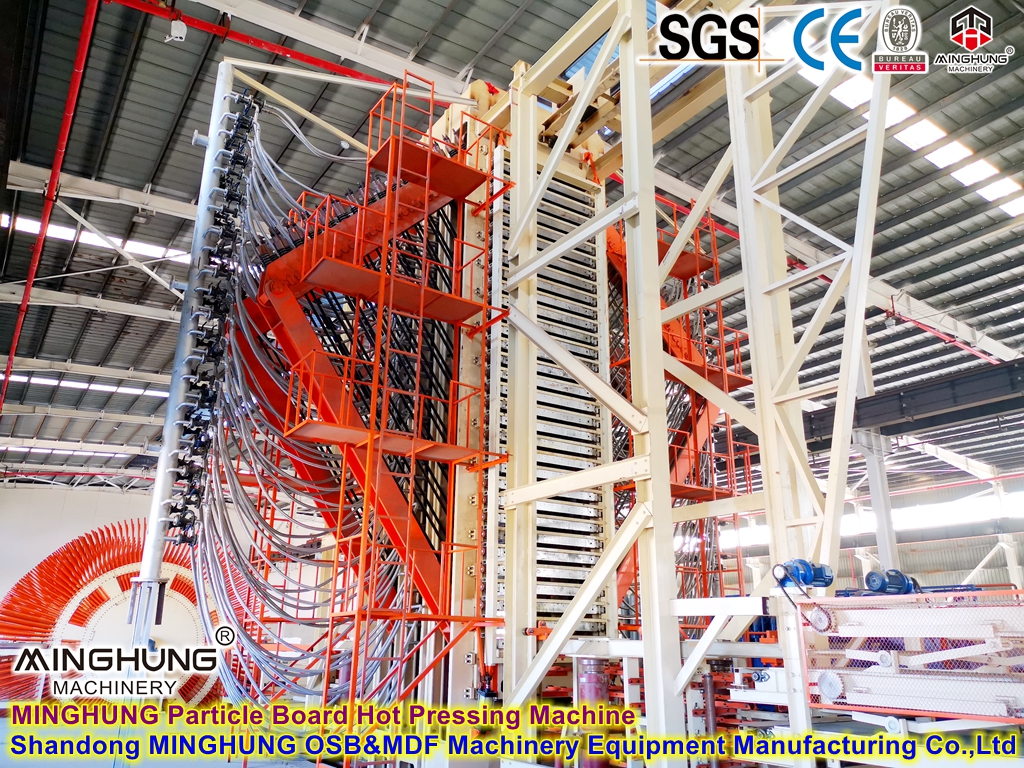

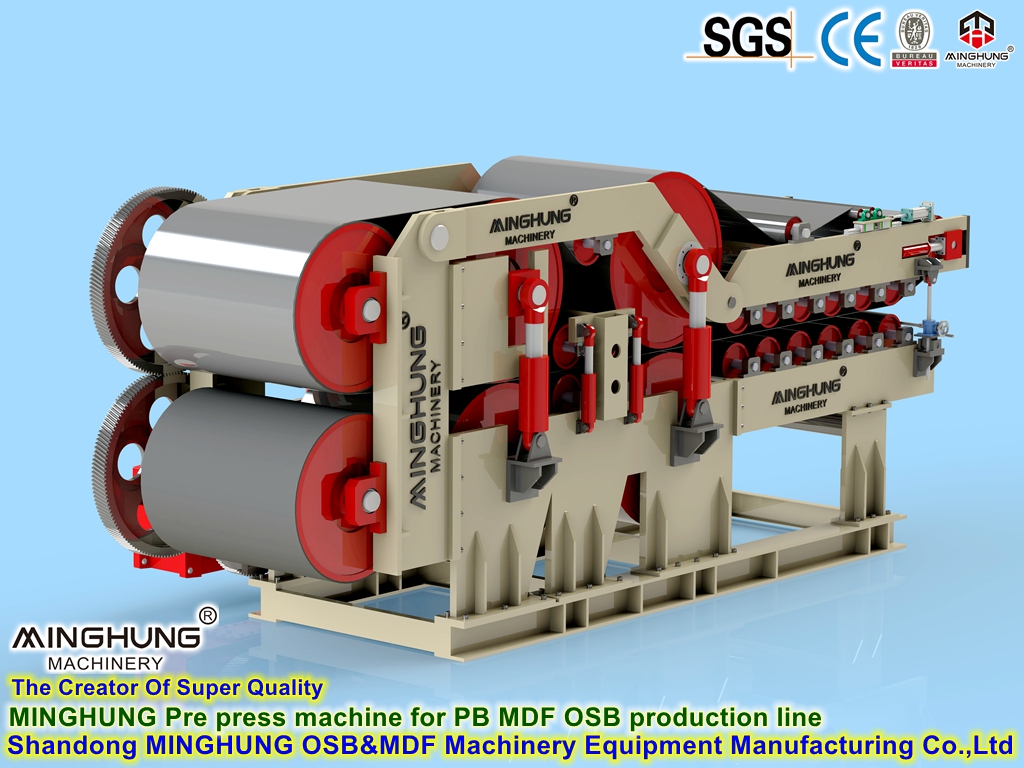

| >>Brief Introduction: Particleboard hot press is one of the main equipment in the production process of particleboard, which is the equipment that the particleboard is sprayed with glue and loaded into the multi-layer press machine with the board loading machine at the same time, and the board is pressed into particleboard.

>>Customized: The hot press machine can be different layers and pressure, and also can be customized to be suitable for different particle board size.

>>How to achieve full automation: Because usually the hot press machine for particle board production, which is high, so it equipped with automatic loading and unloading system, so the whole press process is fully automatic and no need any workers, save labor cost and improve work efficiency. |

02 STRUCTURE

Heating System: Uniform heat distribution, Efficient heating performance Wear-resistant surface treatment, Precision temperature control, High-strength material construction | Hydraulic Station: Stable pressure transmission, Efficient energy conversion High reliability, Intelligent safety protection functions, Easy maintenance |

Pressure Transfer System: Stable pressure output,Precise control of pressure parameters Strong durability, Suitable for different processing requirements, Safe and reliable | Control System: Precise control of the processing process, Programmable operation interface Fault automatic diagnosis, Highly intelligent, Strong customization capability |

Lubrication System: Continuous lubrication protection, Reduced friction loss Increased component life, Efficient energy utilization, Automatic lubrication adjustment | Electrical System: High safety performance, Energy-saving and environmentally friendly Simple and easy-to-understand operation, Fault detection alarm, Efficient energy management |

Safety Protection Devices: Overload protection, Temperature overheat protection Pressure overload protection, Emergency stop button, Safety guard |

03 PRODUCT PARAMETERS

| 40 LAYERS 800 TON FULLY AUTOMATIC HOT PRESS MACHINE |

| 1 | Pressure

| 800tons |

| 2 | Number of plate | 40layers |

| 3 | Plates distance | 100mm |

| 4 | Working pressure | 21kg/cm2 |

| 5 | Hot plate size | 2700*1370*52mm |

| 6 | Total size | 3590*1370*8960mm |

| 7 | Weight | 104tons |

| 30 LAYERS 800 TON FULLY AUTOMATIC HOT PRESS MACHINE |

| 1 | Pressure | 800tons |

| 2 | Number of plates | 30 layers |

| 3 | Plated distance | 100mm |

| 4 | Working pressure | 21kg/cm2 |

| 5 | Hor plate size | 3590*1370*52mm |

| 6 | Total size | 3590*1370*7440mm |

| 7 | Weight | 93tons |

| 10 LAYERS 800 TON FULLY AUTOMATIC HOT PRESS MACHINE |

| 1 | Pressure | 800tons |

| 2 | Number of plate | 10layers |

| 3 | Plated distance | 120mm |

| 4 | Working pressure | 21kg/cm2 |

| 5 | Hot plate size | 2700*1370*52mm |

| 6 | Total size | 3600*1370*4400mm |

| 7 | Weight | 45tons |

04 EXHIBITION

05 COMPANY PROFILE

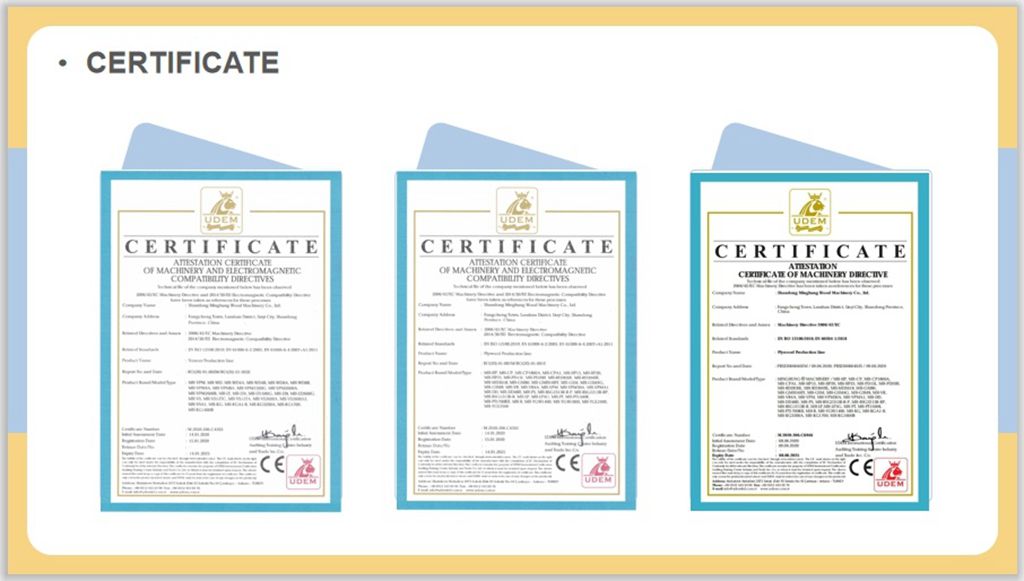

We are China professional factory/manufacturer/supplier of the full line of MDF production line, OSB production line, Particle production line, based on the principle of offer high quality with good materials to each our customer, until now, we have got many clients recognized, which encourge us to continue to offer suitable and good machinery to more people.

As your own conditions, we can design and offer the suitable machine, according to the production capacity, your panel size and other factors.

One full production line, it includes many different machines, and they can be different specification. We will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. And hope that build a good and long-time cooperation.

06 WHY CHOOSE US?

Welcome contact us for more information

Phone number/whatsapp: +86 18769900191 +86 15589105786 +86 15805493072 +86 15805497925

Email: minghungwoodmachinery@gmail.com

Website: www.plywoodmachineline.com