veneer peeling lathe

Dear friends, we are Shandong Minghung Wood Machinery Co.,Ltd This article will tell you the steps for producing wood veneer, some also call it wood foil, and what kind of machines required for producing veneer, after read this, you will know clearly that before you start producing wood veneer, what things you need to do.

Veneer is a thin slice of wood made by rotary cutting or slicing or peeling of the log. The appearance of veneer varies and it depends on how the log is cut. Wood veneer is the material for making plywood, wooden furniture, so if wood veneer quality is very good, the end product like plywood, furniture will be good quality too, this will be very helpful for your business.

And how to produce good quality wood veneer? This is closely related with veneer machine, veneer peeling machine is the necessary machine for producing wood veneer, the principle of veneer peeling machine is: through rotate wood log under the driving of motor, processing wood log into pieces of wood veneer.

Now let’s start one by one :

First: Soften Log:

Before the peeling process, if your wood is very hard, it is better put log into water in order to cut it into smooth veneer of even thickness.

Second: Wood Debarker/log debarker for log rounder wood debarker with wood crusher:

wood log debarker’s function is processing wood for removing bark and make wood round. Wood debarker is easy to operate, and its structure not complex, through the forward and back of hydraulic cylinder, finish the debarking work.

Usually the standard size of log debarker is 4feet and 8feet. the max wood diameter of 4feet machine can be 600mm, the max log diameter of 8feet debarker can be 700mm. And if your log diameter is bigger more, like 1000mm, then should use spindle veneer machine.best wood cutting machinedebarker for chainsaw bardebarker for bandsaw milldebarker for timberking sawmill log debarker debarker for sale in south africadebarker fujihardwood debarker debarker head

Third: Veneer Peeling Machine/spindle less veneer lathe machine:

the spindle less veneer peeling machine,4ft veneer peeling machine,veneer machine,minghung veneer peeling machine,veneer peeling line, consist by machine frame, rollers, motors, electric box, cnc screen, through Setting up the veneer thickness and width through cnc screen, then put log and open starting button, veneer machine will start automatically working. As the peeler wood rotates against the knife, it is peeled into veneer.spindle less veneer peeling lathe veneer peeler veneer peeling machine

Different veneer peeler, different configuration.

If the veneer machine for peeling softwood like poplar, then the machine configuration is common and need not require high, the power of veneer peeling machine also need not too much, because soft wood is more easier to processing.

But if your wood log is hardwood like beech, birch, acacia wood, then it requires the veneer peeler is strong enough, more powerful and heavy duty to keep the wood veneer thickness accurate and balance.

And the speed, thickness range, structure, and others of veneer peeling machine will be different.

The standard size of veneer peeling machine has 4feet(max log length 1300mm) and 8feet(max log length 2600mm), also can be customized according to your conditions.

Four. Veneer Stacker:

The function of veneer stacker is: automatically sorting wood veneer, save two labors, and high efficiency, it connects with wood veneer peeling machine.

Yet, most our clients will but this, because it indeed help a lot, of course, some our clients choose to worker receive wood veneer, this is also no problem.

You can according to your local market, if the labor cost is very cheap, then it is ok that let worker do it, if your labor cost is very expensive, then vacuum veneer stacker machine will help you save a lot and improve work production.

The whole veneer production line with common veneer peeling machine, need 2 workers are enough

The whole veneer production line with high configuration veneer machine just 1 worker is enough.

And make sure offer very good quality and balance wood veneer, will be very helpful for your business.

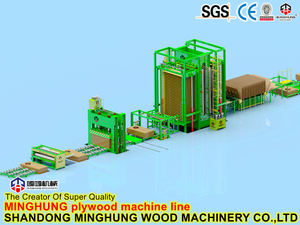

Our Factory:shandong minghung wood machinery co.,ltd

Our factory manufacture plywood machine and wood veneer machine with many years, through continuous improvement and development, our woodworking machine has been very advanced and stable.

Our machine includes: wood debarker,wood rounder,wood peeler,veneer peeler veneer peeling machine,spindle less veneer lathe, veneer peeling line,vacuum veneer stacker, veneer dryer machine, veneer roller dryer, veneer mesh dryer, glue spreader machine, plywood veneer paving line/lay out machine, core composer, plywood cold press machine, plywood hot press machine, plywood edge cutting machine/plywood trimming saw/dd saw, plywood sanding machine, calibrating machine.

Through our engineer continuous test, design and improve machine again and again, now our machine indeed in good character and very stable, but we not satisfied, we will not stop studying and improving, we will continue to make our plywood machine better and better.

because what we want is not just sell our machine, this is not the most important thing, our principle and our value are: letting our plywood machine help your business becoming better, and help you create much benefits, and be your good partner and friend in China.

And we know the low price will not attract more clients if their quality is not good, if just wants to do one time business, this is no benefit for the development of us.

Therefore, our big boss and all staff insist offer good and suitable veneer machine and plywood machine to every our client, and offer good service to them. Help them solve problem, help them earn money. And this is what we are doing.

The world is so big, and there are many suppliers, we are always sincere treat every our client, and the moment when you choose us, that mean you trust us, and we must have to satisfy you and not let you disappoint. This trust is precious, we cherish and protect it.

The function of veneer stacker is: automatically sorting wood veneer, save two labors, and high efficiency, it connects with wood veneer peeling machine.

Yet, most our clients will but this, because it indeed help a lot, of course, some our clients choose to worker receive wood veneer, this is also no problem.

You can according to your local market, if the labor cost is very cheap, then it is ok that let worker do it, if your labor cost is very expensive, then vacuum veneer stacker machine will help you save a lot and improve work production.

The whole veneer production line with common veneer peeling machine, need 2 workers are enough

The whole veneer production line with high configuration veneer machine just 1 worker is enough.

And make sure offer very good quality and balance wood veneer, will be very helpful for your business.

whatsapp: +8615589105786 +8618769900191