plywood making processing plywood manufacturer plywood factory minghung machinery

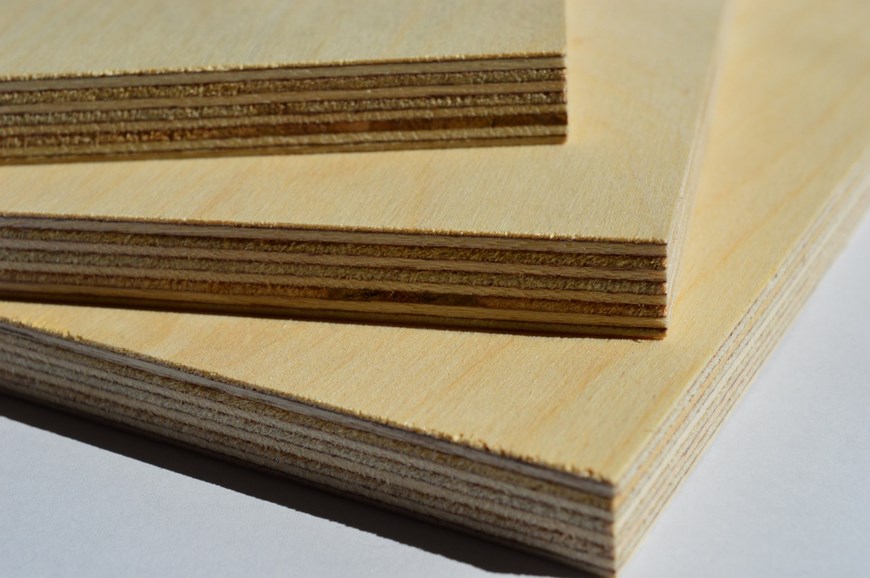

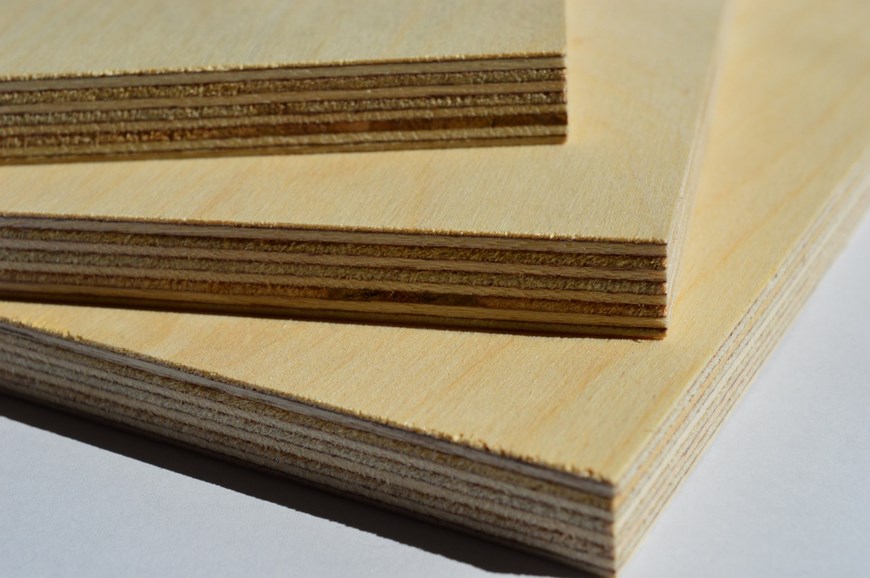

Plywood machine ,plywood process plywood making process is a wood-based panel product comprised of a collection of veneers that are glued together with a resin. To sum up the production process; logs are peeled into veneers, the veneers are lathered in glue, laid up so that the grain direction of each veneer is perpendicular to its adjacent veneer, pressed together, trimmed and sanded.

This article will tell you how to produce plywood, and what kind of machine you need, and how each machine works, after read this, believe you will have new knowledge about plywood machine.

Plywood Manufacturing Steps:

Step 1:

Logs wood timber tree

log is the material for making wood veneer, and wood veneer is the material for making plywood. According to your own market and resources choosing wood, like beech birch pine poplar acacia wood or others.

If the log is very hard, for easy peeling and make sure veneer thickness accurate, people ususally put log into water to boil it, for make sure wood veneer thickness even.

Step 2:

log debarking machine’s function is removing wood bark, and make wood round. Its standard size has 4feet(max log length 1300mm) and 8feet(max log length 2600mm), and max diameter can be 550mm, 700mm, or the debarker details customized according to your own needs. The stucture of wood debarker is not complex, mainly consist by machine frame, rollers, hydraulic station, motors. The operation of log debarker is very easy, there has one handle, just move and back it, wood debarker will forward and back, and removing wood bark under the power of hydraulic cylinder, it can offer enough wood without bark to veneer peeling machine.

Step 3:

Veneer Rotary Peeling Machine.wood clipper machine,spindle less veneer peeling machine veneer peeler

Veneer peeler will process wood into pieces of wood veneer, you can adjust veneer thickness and width by cnc screen, very convenient, and it is english version. usually the thickness range can be 0.5-4.0mm, and if you wants the thickness thinner or thicker, we can customize, like 0.3mm, or 8mm.

The structure of veneer peeling machine consist by: machine frame, rollers, motors, knife. Veneer peeling machine has different types, some is light weight, some is heavy weight, some veneer machine is suitable for peeling softwood, some vneeer peeling machine is suitable for peeling kinds of hardwood. and veneer peeling machine has 4feet and 8feet for your choice, of course, if your size is special, please don’t worry, we will customize veneer peeling machine according to your requires.

As we know, Wood veneer quality is very important for making plywood, if wood veneer thickness very accurate, surface very smooth, then your plywood quality will also be good. So veneer peeling machine is really important for wood veneer quality.

Step 4:

Vacuum Veneer Stacker Machine

This veneer stacker machine’s function is automatially sorting wood veneer, save two workers and improve work efficiency. Veneer stacker will connect with veneer peeling machine, after veneer lathe machine producing wood veneer, the conveyor will transfer wood veneer to veneer stacker, very convenient and high efficiency.

Of course, some clients not use this stacker, and let workers do it, also no problem, but you need afford two workers cost, and the work efficiency not higher than using veneer stacker.

You can decide use this wood veneer stacker or not according to your local market labor cost.

Veneer stacker has 4feet and 8feet size or customize according to your needs.

Step 5:

Veneer Drying Machine veneer dryer machine press veneer dryer press dryer mesh veneer dryer mesh dryer roll dryer

The function of veneer dryer is drying wood veneer to remove abundant moisture. After produced by veneer peeling machine, usually the wood veneer humidity is very high, like 70%, 80%, it is not suitable for making plywood, so we need drying them by veneer dryer machine, the end humidity will be ±10%, and it will be fine for making plywood.

Veneer dryer machine divided into veneer press dryer, roller dryer and face veneer mesh dryer. Veneer press dryer has two types too, one using square tube as material, another using hot plates as material, same as hot press machine. Veneer roller dryer machine drying wood veneer through roller conveyor, it can be different length and width and floors, for example, it can be 20m, 30m, 40m, can be 1 floor, 2 floors, 3 floors, 4 floors, its production capacity will be different. The face veneer mesh dryer machine can drying very thin face veneer, because it conveyor through stainless mesh, so according to your production capacity, wood veneer thickness, budget, factory room choose the better one for you.

Step 6:

Glue Spreader Machine and Lay-up wood veneer

The function of glue spreader is coating glue on surface of wood veneer, glue spreader has single side and double sides at the same time, its size has 4feet and 8feet, the roller diameter is big, the operation of glue spreading machine is very easy, when machine start working, just put wood veneer into it, then wood veneer will be coated into glue, for making plywood.

Step 7:

Hydraulic Cold Press Machine 500ton cold press machine for plywood pre press

The function of cold press is pre-pressing plywood, for conveniently and easy put plywood into hot press machine.

Cold press machine’s structure is very simple, mainly are machine frame, cylinder, hydraulic station.

Its pressure can be 400t, 500t, 600tm, and Usually 500t pressure cold press is popular and enough.

Step 8:

Hydraulic Hot Press Machine 15layer hot press machine melamine hot press machine film faced plywood machine

Hot press is very important for making plywood, through big pressure, plywood press machine will make plywood become strong, make sure plywood quality is good.

Hot press machine’s structure includes: machine frame, hot plates, cylinder, hydraulic station, cnc screen.

Hot press machine can be different layers and pressure according to your needs, layers can be 8, 10, 12, 15, 20, 25, pressure can be 400t, 500t, 600t, 800t, 1000t, 1200t, 1500t

Our plywood hot press machine, using international standard steel material, and good spare parts like simens, schneider, make sure hot press good quality. The hot plates are very hard and flat, make sure pressing your plywood good quality, the cylinder through anti-rust and with tight sealing, all these details make sure our hot press machine for plywood is very strong and good working conditions,

Step 9:

Plywood Saw Machine plywood cutting machine plywood cutter machine

The function of this plywood edge cutting machine is trimming four sides of plywood, make plywood tidiness.

Be guide by infrared, be controlled by micro-computer, automatic trimming, very convenient and high efficiency.

Step 10:

Sanding Machine

The function of sanding machine is: calibrating the plywood thickness, make plywood thickness accurate and balance, the surface of plywood are smooth and bright.

Sanding machine has different types, their advantage are different, some sanding machine mainly for calibrating thickness very well, some sanding machine mainly for polishing plywood surface, some sanding machine is suitable for big production capacity, some is suitable for small, so we will offer the one which is suitable for you.

Our factory produce wood veneer machine and plywood machine mmany years, through continuous improve and develop, our machine now is very stable and advanced, we are one of the big and profvessional factory in China, with professional designer, experienced workers, and good sales team and after sales team, we have ability and confidence that offer you good plywood machine, help your business create much values and benefits.

And we are always your partner in China, always be there support you.

Contacts us

Whatsapp: Mark:+8618769900191 Ali: +8615589105786 Lcinda: +8615805493072

email: shandongminghung@gmail.com