Our clients are satisfied with dryer working condition and drying capacity. and one of Turkey customer ordered second roller dryer, we have delivered, and he introduce other clients to us. because he is very satisfied about our machine.

Before loading, we will first install 3 or 4 sections and test its working conditions and parts are suitable.

During loading, we will packing and Mark, so you will easy to classify different parts.

After loading, we will offer all drawings include foundation drawing and assembly drawing to you. So you can easy to install dryer.

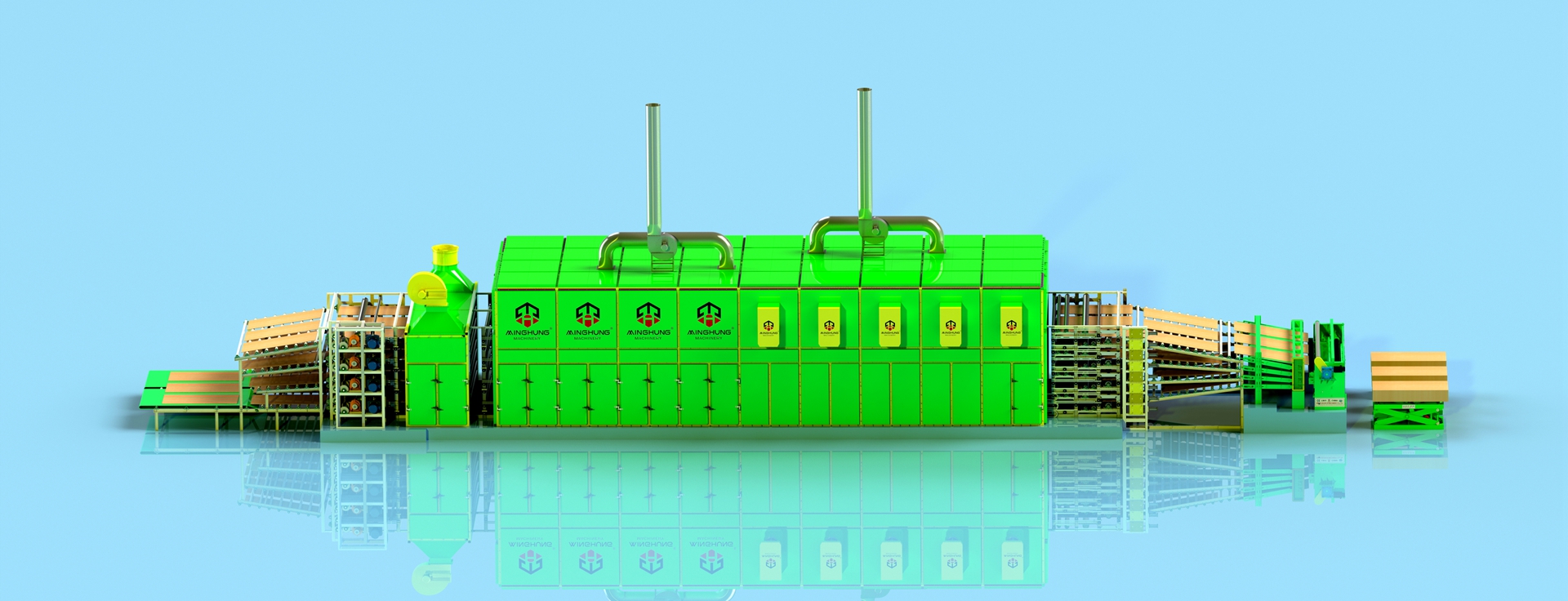

Our factory mainly produce plywood production machine, from the material log, to the end product plywood, we offer these machines. They are: veneer production line, veneer dryer, veneer glue machine, plywood cold press, plywood hot press, plywood sizing machine, sanding machine.

Our factory insist offer good quality machine to each our client, with our machines, you can produce good quality plywood board, and machine will be long life span.

Welcome contact us for more information

We will share machine working video with you, and offer the specification and price for you

Contacts:

Whatsapp:

Mark: +8618769900191

Ali: +8615805496117

Lucinda: +8615805493072

Email: minghungmachinery@gmail.com