New Spindleless Hard Wood Plywood Veneer Production Line

>>>>> Veneer production line Introduction:

Veneer production line

Veneer production line

is the equipment line for veneer manufacturing and making, through process and peel kinds of wood which includes soft wood and hard wood, by set the data from cnc screen, to get the required veneers.

The complete veneer production line includes <1> Log debarker <2> Rotary veneer lathe <3> Log loader <4> Automatic stacker.

With this full veneer peeling line, you can start veneer business, you will get the veneers from raw materials wood.

For the full veneer production line from our factory, this is the new and upgraded type, it is the No.1 in our city( we in Linyi city, Shandong province, China). Because the whole line, we use very good materials and accessories by high and advanced production technology, which can help you produce good quality wood veneers and keep stable & strong by process hard wood like beech, birch and others.

Now let me introduce each detail machine to you one by one

<1> Log debarker

Log debarker

Log debarker

is the first step for the whole veneer production line, it is not complex, its function mainly for remove and peel wood bark.

The whole our debarker machine is heavy and strong, keep stable and easy to peel kinds of wood.

Its operation way is also very simple, when running debarker, put wood into debarker, workers just move the handle forward and backward, then debarker will rotate wood and peel it.

| Name | Log debarker |

| Max peeling length | 1400mm /2600mm / or customized |

| Max peeling diameter | 500mm |

| Speed | 70m/min |

| Operate way | Move the handle forward and backward |

| Weight | 5000kgs |

<2> Rotary veneer lathe

Rotary veneer lathe

Rotary veneer lathe

Is the most important machine during the full line. It will peel wood without bark into pieces of veneers.

Through the cnc screen, you can set veneer thickness, cutting width, machine working speed as you want, very conveniently.

One set good veneer lathe, it can peel kinds of hard wood, and make sure the peeled veneers high accurate and smooth surface, and veneer machine can keep good conditions always.

We can say that our this type veneer peeler, it is.

| Name | Rotary veneer lathe |

| Max peeling length | 1400mm /2600mm / or customized |

| Max peeling diameter | 500mm |

| Thickness | 1-3mm |

| Speed | 30-100m/min Adjustable |

| Power | 47.5kw |

| Knife | Hydraulic knife system |

| Weight | 7000kgs |

<3> Log loader

Log loader

Log loader

Is the one for automatically convey wood into debarker and veneer lathe.

For the complete veneer production line, it includes two pieces log loader

<4> Automatic stacker

Automatic stacker

Automatic stacker

Is the one on the last step, connects with rotary veneer machine, for automatic stacking peeled veneers, help you save labor cost and improve work efficiency.

| Name | Automatic papel stacker |

| Stacking height | Max 1200mm |

| Speed | Adjustable to match veneer lathe |

| Veneer thickness | 1-3mm |

| Weight | 2200kgs |

Note: the specific veneer machine specification can be customized according to your own conditions.

>>>>> Veneer machine advantages

Hydraulic knife holder

Automatic open and close, easy to change blade.

Linear giude

Keep high accuracy when veneer machine running, keep long life span

CNC screen

You can set veneer data from here, conveniently

Servo motor

The cutting motor and Feed motor all Servo motor, keep high accuracy

>>>>> Veneer machine at our clients factory

Until now, we have exported many veneer peeling machine and wood debarker to different countries, and got good feedback. many our clients have bought three or four veneer production line from us. As long as they want the veneer machine, they choose us.

>>>>> MINGHUNG veneer machine loading pictures

Before loading your veneer machine, first we will assembly it and test it, and share your veneer machine's test video with you. After we checked and confirmed all is fine of your machine, then we disassembly and packing and loading for you.

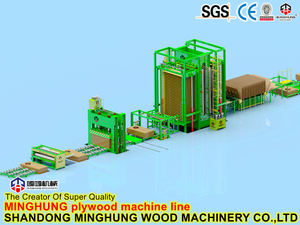

>>>>> Who we are?

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.

Our company integrates design, research and development, production and sales, and works closely with China's advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents.

Pay more attention to machine details, details determine sucess or failure, so we continuous improve and optimize machines' performance, strictly control each production step, using advanced lathe processing machine, and through many times inspections, make sure our machine accurate and durable.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers.

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, sanding machine.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

>>>>> Related veneer machine:

Knife grinder

It is for grinding blade edge when blade become blunt, if blade become blunt, you need to change blade quickly, or it will also affect veneer quality. One good and sharp blade, will be helpful for good veneers.

Veneer drying machine

It is for drying peeled veneer humidity, the original veneer humidity is high and different according to different wood species, and it is not suitable for making kinds of end products like plywood, furniture. So veneer drying machine will make the dryed veneer humidity is low and suitable.

>>>>RFQ:

How long of your machine warranty?

2 years for main parts.

The production time?

1 month.

Payment terms:

T/T. 30% deposit, 70% before delivery.

Will you help me solve when i meet problem about machine?

We will at the fist time reply you and help you solve.

Will you engineer come to install machine?

Yes, when machine soon reach your factory, our engineer will go to your factory.

Welcome contact us for more information of the veneer production line and other plywood machinery

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.