how to produce veneer?

Hello I am Lucinda, the sales manager of SHANDONG MINGHUNG WOOD MACHINERY CO.,LTD.

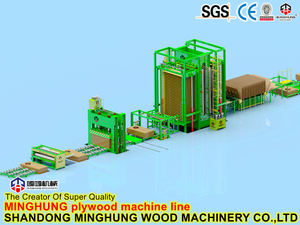

our factory produce the whole line of plywood machine and wood veneer machine, from the beginning to the end, includes the log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer mahcine, glue machine, cold press machine, hot press machine, plywood saw machine, sanding machine.

today i am gonna introduce the plywood manufacturing technique for you, thus if many friends wants to produce plywood, but not clearly know the process of plywood making, then this article will help you.

first, as we know, for making plywood, wood veneer/wood papel is necessary, it is the material of plywood board.

how to produce wood veneer?

this require log lathe includes wood debarker, veneer peeling machine, log transporter, vacuum veneer stacker, this veneer production line, to process tree into pieces of wood veneer.

our veneer peeling machine is very strong which can peel kinds of hardwood, and the log peeler can keep stable when working, the most important is that machine can help you produce good quality wood veneer. this will be big helpful for help your business better, whatever you will produce plywood by yourself, or sell the wood papel to plywood factory, or make other products like wooden furniture.

after produce the material---wood veneer.

need dry wood papel by veneer dryer machine. because the original humidity of wood veneer is very big, different wood different moisture, some about 60%, some about 70%, this can not making plywood.

veneer dryer machine includes: veneer press dryer, roller dryer, mesh dryer. they have their own advantages and characters.

for example, if you require big capacity one day, then the roller dryer is the better choice for you. if your thickness is very thin, then the mesh dryer will more suitable for you.

the roller dryer and mesh dryer can be different floors like 2 floors, 3 floors, 4 floors, and can be different length like 20m, 24m, 30m or more.

So we usually offer the suitable dryer according to our clients own conditions and requires.

the next step is gluing by glue spreader/glue machine, becuase after coating glue on the surface of wood veneer, thus workers can lay them out into plywood size.

glue spreader machine has 4feet and 8feet, they are standard size, usually directly choose double sides at the same time is better, this can improve your work efficiency and save time.

after gluing wood veneer, and lay out them.

the next step, is transport the board to the cold press machine, also be called pre-press machine, because it first press plywood before the hot press machine.

plywood cold press machine have two types, one is the cylinder press from the top to the bottom, another is the cylinder press from the bottom to the top.

the pressure can be 500ton 600ton, its standard size for make 4*8feet plywood board. but some clients produce the bigger plywood panel or smaller plywood panel, also no problem, because we can customize cold press according to your needs.

the next step is hot press machine, the function of hot press is through the big pressure pressing plywood into one solid board.

hot press machine can be different layers like 10layers, 12layers, 15layers, 20layers, 25layers or more, and can be different pressure like 500ton, 600ton, 800ton, usually these three pressure are common and popular and enough for making plywood. but some clients plywood board is big and thickness is very thick, this time the hot press machine's pressure bigger is better like 1200ton.

after pressing plywood well, then transport to the plywood edge cutting saw machine, because when worker lay out plywood, the edges of plywood must not same and tidiness. this is why we need the plywood saw machine. for trimming four edges of plywood, make each plywood size same and the edges are tidiness.

plywood saw machine has two types, the first one is common type, the second one is roll type saw. most clients choose the first type, becuase compare with roll type edge cutting saw, it is more favorable, and working good.

but if you wants to improve the working efficiency, and using automatic infeeding device, the second type roll type is a better choice for you.

the last step, sanding machine.

sanding machine has different types and configurations, it can be one head sanding machine, two heads sanding machine, three heads sanding machine, it can be single side plywood sander, also can be double sides plywood sander. some plywood sanding machine mainly for calibrating the plywood thickness, some sander for polishing the plywood surface.

so we usually offer the suitable one after know clearly about our clients requires.

yet, the whole step for making plywood has finished.

reading now, i think you have had some thoughts about how to prodce plywood, and what kind of plywood machine do you need.

if you wants to start produce plywood, or you wants to enlarge your plywood machine, welcome contact us.

we will offer you the suitable and good plywood machine.

CONTACTS:

Ali: +86 15805496117

Mark: +86 18769900191

Lucinda: +86 15805493072

Email: minghungmachinery@gmail.com

http://youtu.be/vnwMkuJPf60