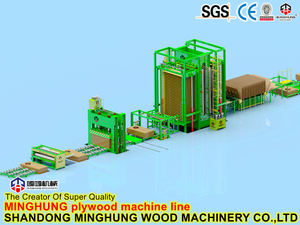

Improving Compressed wood Creation Productivity with Cutting edge Facade Drying Machines

Presentation:

In the realm of compressed wood creation, the drying system assumes a vital part in guaranteeing the quality and sturdiness of the eventual outcome. Facade drying machines have changed the business, giving a more productive and successful strategy for drying compressed wood facade. In this article, we will investigate the advantages and elements of these high level machines, and how they add to upgrading compressed wood creation effectiveness.

1. Understanding Facade Drying Machines:

Facade drying machines are explicitly intended to dry compressed wood facade, guaranteeing that they arrive at the ideal dampness content for additional handling. These machines use creative advances and exact control frameworks to accomplish steady and uniform drying results. By controlling temperature, stickiness, and air course, facade drying machines establish the best climate for fast and effective dampness evacuation.

2. Expanded Effectiveness:

One of the vital benefits of utilizing facade drying machines is the huge expansion underway proficiency. Customary drying strategies frequently call for a significant measure of investment, bringing about longer creation cycles. With cutting edge facade drying machines, the drying system is sped up, considering quicker completion times and expanded efficiency.

3. Worked on Quality:

Compressed wood created from appropriately dried facade displays predominant quality and toughness. Facade drying machines guarantee that the dampness content is painstakingly controlled, forestalling issues like distorting, breaking, or delamination. By accomplishing steady drying results, these machines add to the development of excellent compressed wood that fulfills industry guidelines.

4. Energy Effectiveness:

As well as improving creation productivity, facade drying machines are intended to be energy-effective. They use progressed heat recuperation frameworks and protection materials, limiting energy utilization and decreasing functional expenses. This advantages the climate as well as makes these machines a practical speculation for compressed wood producers.

5. Customization and Flexibility:

Current facade drying machines offer an extensive variety of customization choices to take special care of various creation necessities. They can be changed in accordance with oblige different facade thicknesses, dampness content levels, and types of wood. This adaptability permits pressed wood producers to improve the drying system as indicated by their particular necessities, further upgrading by and large effectiveness.

6. Remote Observing and Control:

Many high level facade drying machines are outfitted with remote checking and control abilities. This element empowers administrators to screen and change the drying boundaries from a concentrated area, working on functional comfort and decreasing the requirement for consistent on location oversight. Remote observing additionally works with opportune investigating, limiting personal time and augmenting creation productivity.

End:

The presentation of cutting edge facade drying machines has essentially changed the compressed wood creation industry. Their capacity to upgrade effectiveness, work on quality, and diminish energy utilization makes them an important resource for compressed wood producers. By putting resources into these creative machines, makers can smooth out their creation processes, increment efficiency, and convey great compressed wood items to satisfy the developing business sector need.

Veneer drying is a very important link in the production process of plywood. The moisture content of veneer is too high, or the moisture content of veneer is uneven, which directly affects the production quality of plywood. Usually, the moisture content of veneer is required to be %8-%14 , the moisture content of the veneer in this interval is the most reasonable for the quality of the plywood veneer, so a veneer dryer is required to complete the veneer drying. The selection of the veneer dryer needs to provide us with several data to ensure that we provide the best solution:

Veneer drying is a very important link in the production process of plywood. The moisture content of veneer is too high, or the moisture content of veneer is uneven, which directly affects the production quality of plywood. Usually, the moisture content of veneer is required to be %8-%14 , the moisture content of the veneer in this interval is the most reasonable for the quality of the plywood veneer, so a veneer dryer is required to complete the veneer drying. The selection of the veneer dryer needs to provide us with several data to ensure that we provide the best solution:

1. What is the thickness of the veneer?

2. What is the throughput for 10 hours?

3. What is the moisture content of the veneer?

4. The name of the tree for the veneer?

5. Is the heating boiler heat transfer oil or steam? Etc.,

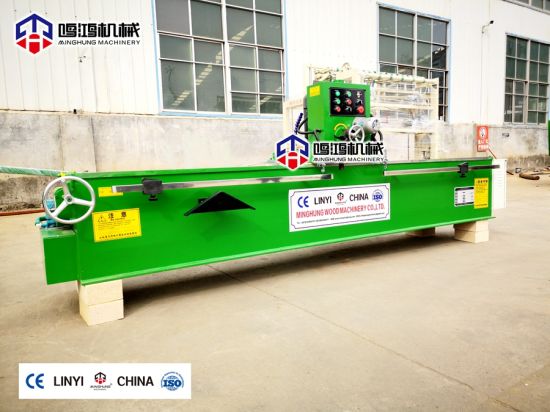

MINGHUNG MH-304HL model dryer, providing energy-saving and efficient veneer drying solutions. Veneer drying parts:

FAN:

We have professionally designed according to different types of dryers, positive pressure fans and negative pressure fans, different fans for different veneer drying equipment, energy-saving, high-efficiency design concepts provide an effective guarantee for improving the quality of veneer drying products .

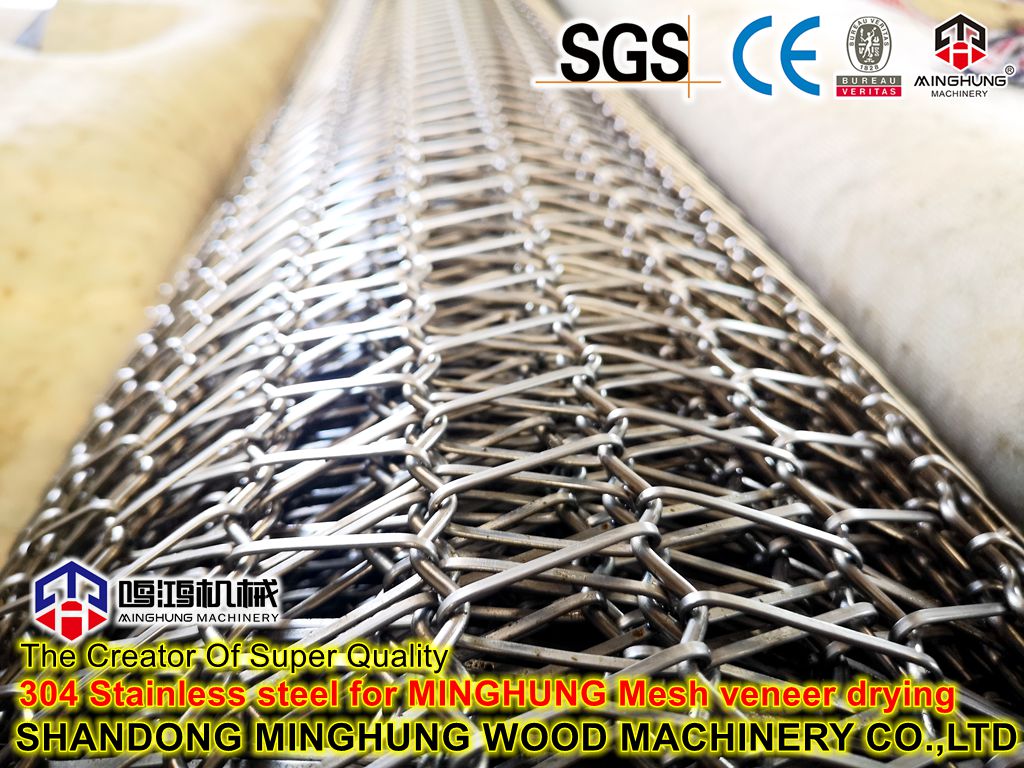

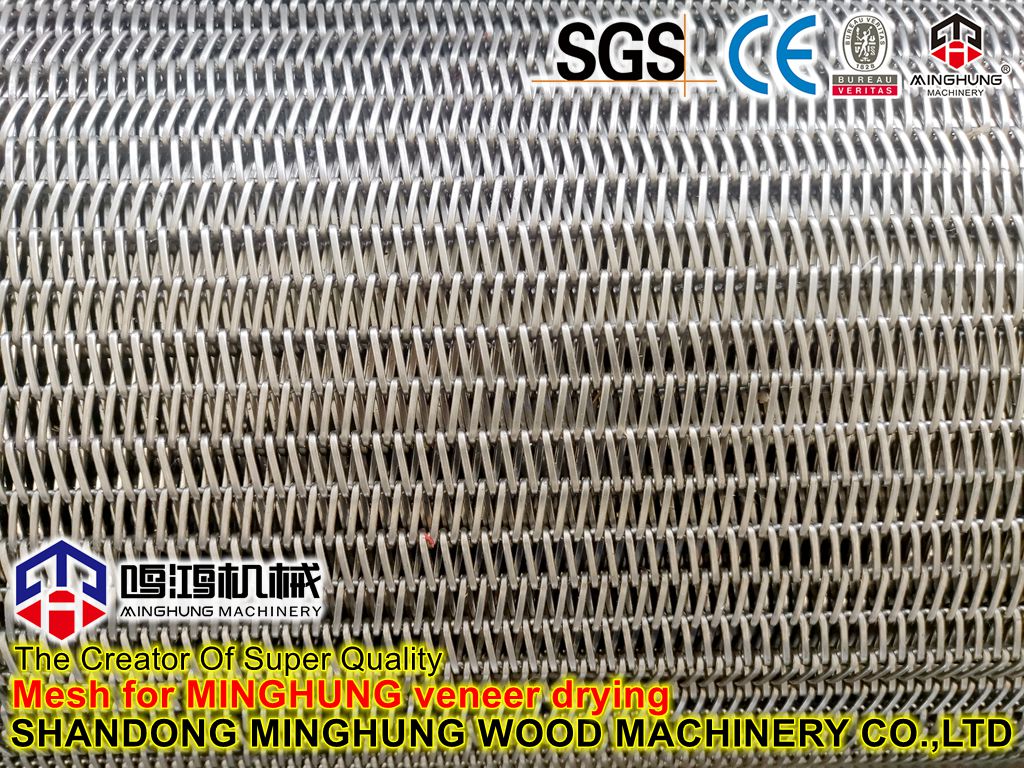

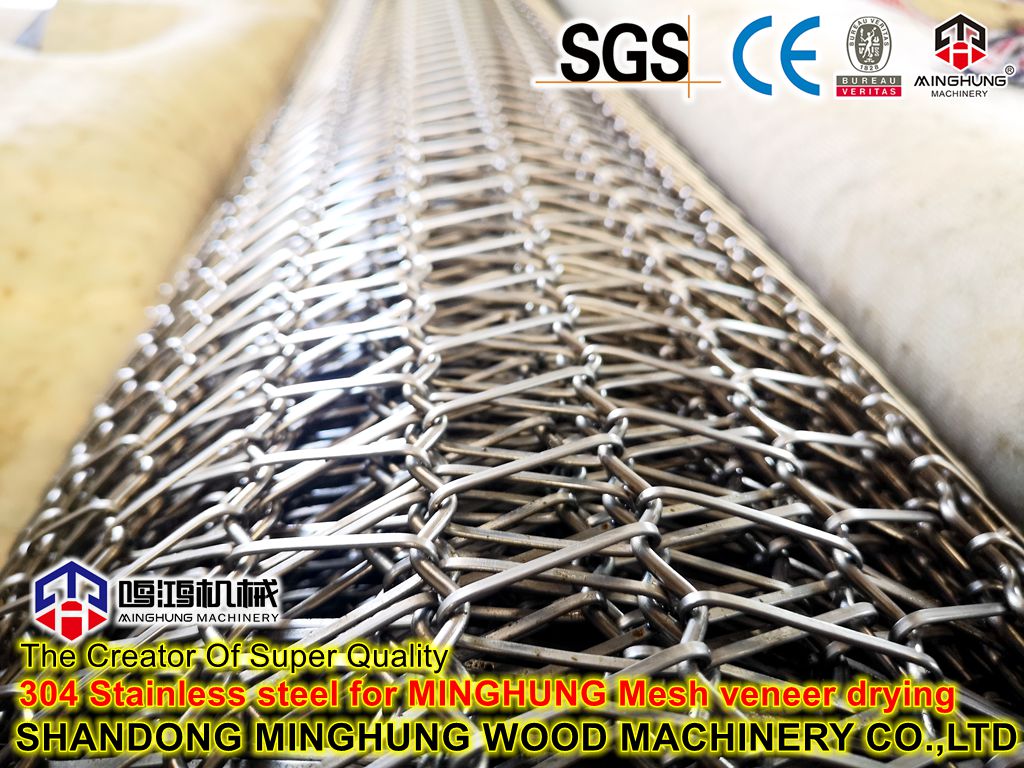

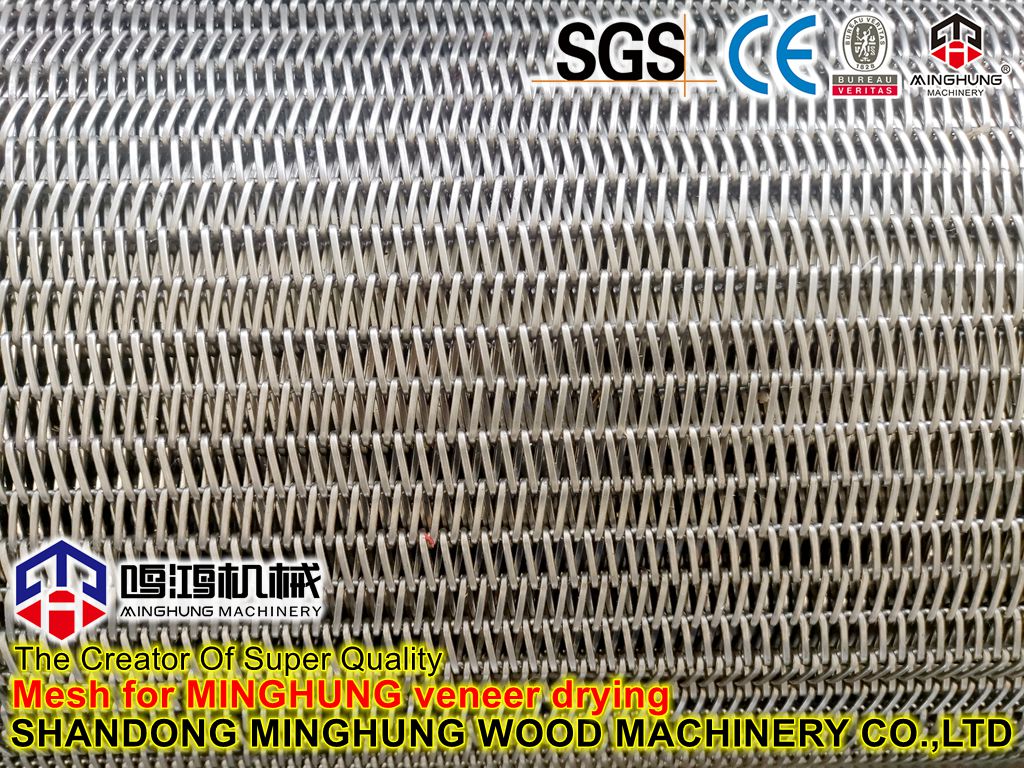

MESH AND ROLLER:

HEAT CONDUCTION HEAT SINK:

Heat conduction heat sink, used for MINGHUNG veneer drying, the warp is made of aluminum, the characteristics of aluminum material is good heat conduction effect, low heat loss, can better improve heat conduction efficiency, internal design forced circulation, heat conduction effect is better than traditional heat dissipation Warp increased by %70. Greatly improved energy utilization.

Delivery:

Heat conduction heat sink, used for MINGHUNG veneer drying, the warp is made of aluminum, the characteristics of aluminum material is good heat conduction effect, low heat loss, can better improve heat conduction efficiency, internal design forced circulation, heat conduction effect is better than traditional heat dissipation Warp increased by %70. Greatly improved energy utilization.

Heat conduction heat sink, used for MINGHUNG veneer drying, the warp is made of aluminum, the characteristics of aluminum material is good heat conduction effect, low heat loss, can better improve heat conduction efficiency, internal design forced circulation, heat conduction effect is better than traditional heat dissipation Warp increased by %70. Greatly improved energy utilization.